- Production - Materials - Metrology

- Production machine

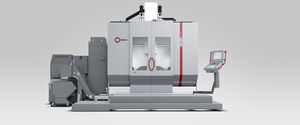

- 5-axis machining center

- MASCHINENFABRIK BERTHOLD HERMLE AG

5-axis machining center C 22 horizontalfor aeronautics

Add to favorites

Compare this product

Characteristics

- Number of axes

- 5-axis

- Spindle orientation

- horizontal

- Applications

- for aeronautics

- Rotational speed

15,000 rpm, 18,000 rpm, 25,000 rpm, 30,000 rpm, 42,000 rpm

(94,248 rad.min-1, 113,097 rad.min-1, 157,080 rad.min-1, 188,496 rad.min-1, 263,894 rad.min-1)- X travel

450 mm

(17.72 in)- Y travel

600 mm

(23.62 in)- Z travel

330 mm

(12.99 in)

Description

As the C 12’s bigger brother, the C 22 High-Performance-Line machining centre has the same collision circle with longer traverse paths and larger component dimensions – and that means a huge degree of flexibility.. The C 22 impresses with a large number of features. This predestines the C 22 for an especially wide range of applications, as the following examples show.

Short process cycles, quick workflows and the highest possible machine dynamics:: The flexible C 22 machining centre is ideal for machining high-value parts with excellent accuracy and small tolerances. As with most Hermle machining centres, the height-adjustable control panel can be altered to suit the operator’s working height. You can discover more details about the C 22 via the i-buttons in the 360 degree view.

7 reasons for a C 22

They’re as reliable as a goalkeeper on his line, and as precise as a golfer’s putt – our machining centres prove their star qualities in all kinds of different industries whenever efficient and powerful milling and turning are needed. Get the best results, and make it to the top in all kinds of disciplines!

HIGH-TECH TOOL SPINDLES WITH COLLISION PROTECTION

The slimline tool spindles are constructed in two parts and can be replaced easily and quickly during servicing. Thanks to low interfering edges and collision protection by

compression sleeves, safety is given primary importance by maximum collision avoidance. Damage can be prevented in 50 % of collisions.

VIDEO

Other MASCHINENFABRIK BERTHOLD HERMLE AG products

Machining centres

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.