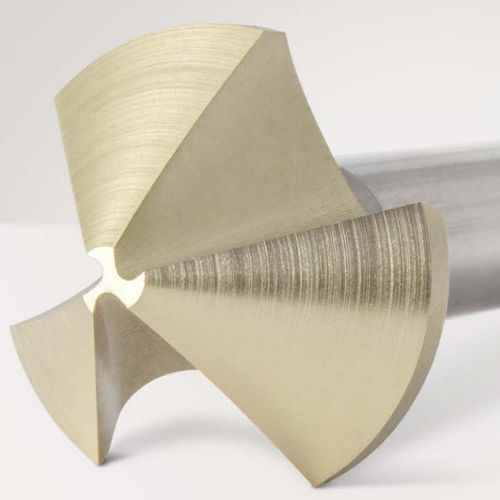

Conical milling cutter COS seriescarbideHSSfor metal

Add to favorites

Compare this product

fo_shop_gate_exact_title

Characteristics

- Geometry

- conical

- Material

- carbide, HSS

- Dispensed product

- for metal

- Other characteristics

- for the aerospace industry

- Diameter

Min.: 4.3 mm

(0.169 in)Max.: 31 mm

(1.22 in)- Length

Min.: 40 mm

(1.57 in)Max.: 71 mm

(2.8 in)

Description

Every machining process has latent potential

for boosting productivity. There is significant

potential for improvement even in seemingly

secondary machining operations. This issue is

demonstrated by the new generation of countersinks.

The newly developed countersink operates

with significantly reduced axial forces. The

cutting edges on the countersinks have an

unequal spacing. With this spacing, the axial

forces are reduced by more than 50% and the

radial forces by 25% compared with conventional countersinks. Such optimised operating

conditions create far less vibrations at the

tool, allowing higher accuracies and better

surface finishes to be achieved. The precision of the countersink leads to an immediately improved contact of bolted and riveted

joints, eliminating settling of the joint under

load after assembly. The reduced load on the

machine also increases the life of the tools.

Thanks to the smooth and stable running, the

tools can also be operated with higher cutting

values. The result is significant time savings.

Catalogs

No catalogs are available for this product.

See all of MAPAL FRANCE‘s catalogsRelated Searches

- Aeronautic milling tool

- Metal milling cutter

- Carbide milling tool

- Aeronautic drill bit

- Solid drill bit

- Metal drill bit

- Milling tool for the aerospace industry

- Carbide drill bit

- Aeronautic chuck

- Chuck

- Aeronautic reamer

- Reamer

- Aeronautic cutting insert

- Cutting insert

- Monobloc reamer

- Composite cutting insert

- Metal reamer

- Tool holder

- Insert reamer

- Insert drill bit

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.