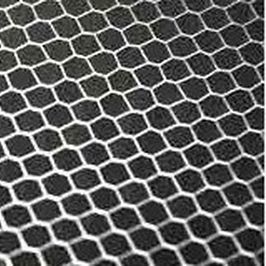

Aluminum honeycomb 5056 seriesfor aeronauticsfire-resistant

Add to favorites

Compare this product

Characteristics

- Material

- aluminum

- Applications

- for aeronautics, fire-resistant

- Length

1,220 mm

(48 in)- Width

2,440 mm

(96 in)

Description

The honeycomb aluminum aeronautical grade is produced by thin aluminum strip of 5000. The protection is applied on the tape against corrosion of atmospheric agents. There are several sections of cells and density. The honeycomb is produced by bonding aluminum sheets that damage all'esagno expanded form.

The honeycomb can be provided in blocks, unexpanded strips and expanded sheets. The thickness is chosen by the customer. The material can be perforated for communicating all the cells between them (for vacuum application and space). Some cells can be expanded in OX shape (rectangular) to allow the curvature in one direction.

Features

- High resistance to compression and shear /Weight reduction

- Corrosion resistant and fire / recyclable material

Applications

It is used in various aero fields (airplanes, helicopters, radar), automotive (racing cars), RF shelding ensuring a long life and resistance to moisture and temperature.

Dimensions

The standard size is mm1220x2440. General tolerances - 50 / + 100 mm

On request special sizes. The thickness is chosen by the customer: minimum 1.5 mm up to 500 mm depending on the type of cell. Tolerance standard +/- 0.12 mm or +/- 0.05mm with extracost.

Designation

The full description of the honeycomb provides:

Alloy: description of the type of aluminum alloy used (5056)

Density: the weight of material expressed in pounds per cubic feet or kg/m3

Cell: distance between two sides of the hexagon (mm or fraction of an inch)

Foil Nom: thickness of the wall that makes up the hexagon (mm or inches)

P or N : material can be supplied perforated or non perforated

Tolerances + / - 10%

Catalogs

No catalogs are available for this product.

See all of I MA TEC SRL‘s catalogsRelated Searches

- Adhesive

- Aeronautic adhesive

- Epoxy adhesive

- Bonding adhesive

- Metal adhesive

- Plastic adhesive

- Glass adhesive

- Composite adhesive

- Two-component adhesive

- Aeronautic honeycomb

- Aeronautic prepreg

- Prepreg

- Resin prepreg

- Viscosity adhesive

- Aluminum honeycomb

- Single-component adhesive

- Epoxy resin prepreg

- Carbon fiber prepreg

- Aramid paper honeycomb

- Fiberglass prepreg

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.