- Airport terminals

- Cargo handling

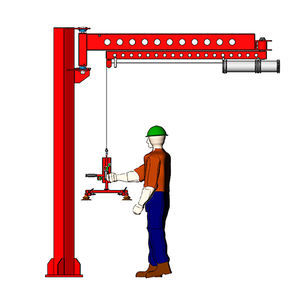

- Lifting system for the aerospace industry

- LIFTS ALL AIRPORT HANDLING SOLUTIONS

Lifting system for the aerospace industry for airport

Add to favorites

Compare this product

fo_shop_gate_exact_title

Characteristics

- Applications

- for airport, for the aerospace industry

- Carrying capacity

600 kg

(1,322.774 lb)

Description

A complete ergonomic lifting system consists of three parts:

– a traverse system or jib crane that enable the load to be moved freely within a certain perimeter.

– the Bal-Trol, that makes the load weightless and is used to raise and lower it.

– the Gripper a type of lifting tool that grips the load using either vacuum suction cups, mechanical grippers or a hook.

An ergonomic lifting system from Lifts All consists of an overhead rail system or crane, the pneumatic hoist Bal-Trol, and a lifting tool (a gripper, as we call it). Such systems guarantee safe, ergonomic and energy-efficient material handling. Most warehouses and factories benefit from using a lifting system. Installing a gripper in a production process, on an assembly line or at work-points where repetitive lifting movements occur, can make a huge difference. Because the loads feel weightless, heavy lifting work becomes easy. The operators’ body posture and movements become normalized. Traditional working rolls that required physical strength can now be carried out by anyone. Thus, contributing to having a healthier staff and less sick-leave absentees.

We tailor make our lifting systems to our customer’s specific needs and their working spaces. With the help of a complete lifting system, workers are able to lift sacks, boxes, barrels, rolls and much more, efficiently and ergonomically.

Components of a complete lifting system

Customized overhead rail systems and jib cranes provides flexibility in moving goods around in larger working areas. Based on your needs, we can provide solutions to ensure an effective workflow just for you.

Catalogs

No catalogs are available for this product.

See all of LIFTS ALL AIRPORT HANDLING SOLUTIONS‘s catalogsOther LIFTS ALL AIRPORT HANDLING SOLUTIONS products

LIFTING TOOLS

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.