- Production - Materials - Metrology

- Production machine

- LAPMASTER WOLTERS GMBH

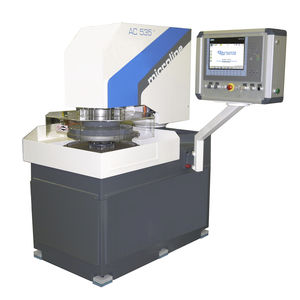

Machining finishing machine AC microLine® 1000grindingfor aeronauticsautomatic

Add to favorites

Compare this product

Characteristics

- Associated function

- grinding, machining

- Other characteristics

- for aeronautics, automatic

- Power

6 kW

(8.16 hp)

Description

The Peter Wolters AC microLine® 1000 double-side batch processing machine has been designed for high precision series processing of medium sized work pieces. Due to its modular construction, the AC 1000 can be used as a fine grinding, and honing machine.

Designed for high-precision processing of work pieces

Suited for fine grinding and honing

Optimum surface quality, flatness, thickness tolerance and

plane parallelism with tightest tolerances on the work piece

AC 1000 can be linked with manual, semi-automatic or fully automatic loading systems

Fast and ergonomic loading and unloading

Upper working wheel can swivel out for total access to the process area

Extreme temperature stabilization over the tool surface

User friendly, intuitive operation

Excellent machining results and precision

Low operating costs

Individual process development

Easy to maintain

High-precise non-contact measuring control

Powerful drive technology

High-precise pneumatic load system

High production reliability

Stable cast iron base frame

Siemens PLC Control and

Siemens KP1200 Comfort Panel

Remote maintenance solution

RangeCare® via mobile

communications or VPN

Catalogs

AC microLine® 1000

2 Pages

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.