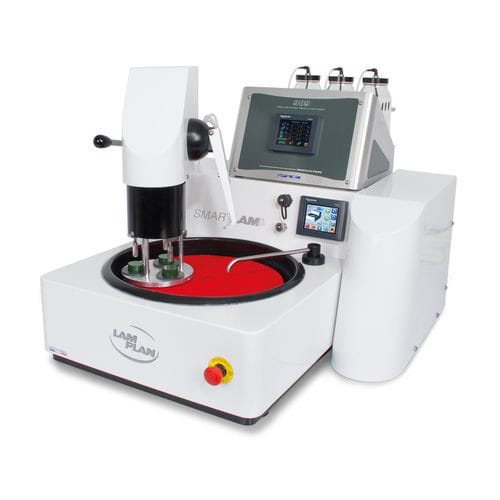

Metal polishing machine SMARTLAM®3.0semi-automaticfor aeronautics

Add to favorites

Compare this product

Characteristics

- Material

- for metals

- Control type

- semi-automatic

- Other characteristics

- for aeronautics

Description

With the SMARTLAM®3.0, LAM PLAN proposes an economic solution in terms of automatic pre-polishing and polishing of metallographic samples.

The SMARTLAM®3.0 is equipped with a new specific motorised head, composed with a 3 cells sample-holder and an individual pneumatic pressure system.

The moto reducer group has a high torque, the speed and the rotation can be set. The individual pneumatic pressure system handled by the electronic proportional valve, assures a great polishing regularity. The pressure applied per sample goes from 5 to 60 N.

The SMARTLAM®3.0 uses the reliable and proven base of the SMARTLAM®2.0 from which it conserves all the assets for a manual use (activation/deactivation of the sample holder head with the touch screen). The plate’s speed and rotation can be set from 20 to 650 rpm.

All the functions accomplished by the machine or the head are controlled by the screen. The programs can be stored in the intern memory.

For more efficiency, you can connect the M.M. 909 M automatic dosing unit to your SMARTLAM® 3.0 and benefit of a very economic and competitive set.

Plate capacity

Ø 200 to 300 mm

Body

Steel coated with epoxy paint

Bowl

Removable resin basin for easy cleaning

Controls

3,5“ touch screen to control the machine: start/stop, timer, speed and direction of plate, water solenoid valve

Plate rotation speed

Variable from 20 to 650 rpm

Rotation

Clockwise / counter-clockwise

Programming

Loads 9 programs

Connection

Slave connector for dosing unit

Water inlet

Removable pipe with flow-rate adjustment and safety solenoid valve

VIDEO

Catalogs

No catalogs are available for this product.

See all of LAM PLAN SA‘s catalogs*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.