- Components - Spare Parts

- Landing and Braking

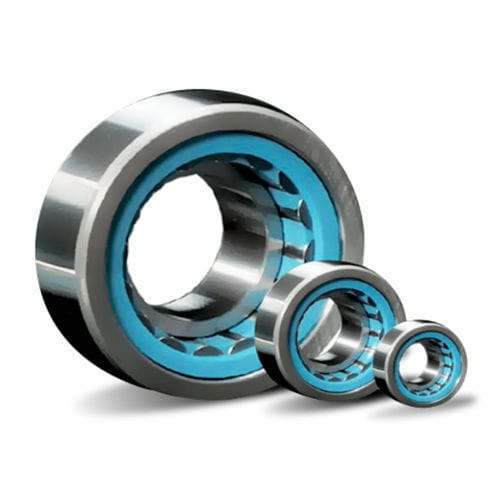

- Cylindrical roller bearing

- KOYO BEARINGS VIERZON MAROMME (GROUPE JTEKT)

Cylindrical roller bearing needlesmallfor airliners

Add to favorites

Compare this product

Characteristics

- Rolling element

- cylindrical roller, needle

- Other characteristics

- small

- Applications

- for airliners

Description

It was developed by Koyo for applications where oil or grease does not provide the best lubricant solution.The solid lube is inserted into the bearing in an injection molding machine.

The compound of polyethylene, synthetic oil (~70%) and additives, provides a long lasting (forced) lubrication.

This lubrication technology is specifically interesting for severe operating conditions like oscillating movements, or moderate speed/high load applications.

This type of lubrication is not suitable for applications where operating temperatures of more than 85 degrees are reached.

Solid lube is currently offered for application in Needle -and Cylindrical roller bearings for which a sufficient volume is needed to justify the (small) investment for the unique injection mold, which is required for each bearing type & size.

For more background information and details please refer to the Koyo Solid Lubrication Technology flyer, which can be downloaded here or contact us directly via: jaap.tenkate@jtekt.com

Catalogs

No catalogs are available for this product.

See all of KOYO BEARINGS VIERZON MAROMME (GROUPE JTEKT)‘s catalogsOther KOYO BEARINGS VIERZON MAROMME (GROUPE JTEKT) products

PRODUCTS

Related Searches

- JTEKT bearing

- Ball bearing bearing

- JTEKT airliner bearing

- Steel bearing

- JTEKT roller bearing

- JTEKT radial bearing

- Precision bearing

- Double-row bearing

- Single-row bearing

- Angular-contact bearing

- Pre-lubricated bearing

- Heavy load bearing

- Deep groove bearing

- Cage assembly bearing

- Axial bearing

- Cylindrical roller bearing

- Self-aligning bearing

- Sealed bearing

- High-speed bearing

- Stainless steel bearing

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.