- Production - Materials - Metrology

- Production machine

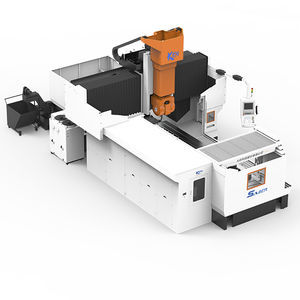

- 5-axis machining center

- KEN ICHI MACHINE CO., LTD

5-axis machining center Rhino 1700horizontalfor aeronauticsCNC

Add to favorites

Compare this product

Characteristics

- Number of axes

- 5-axis

- Spindle orientation

- horizontal

- Applications

- for aeronautics

- Other characteristics

- CNC, with moving table, double-column

- Rotational speed

50 rpm

(314 rad.min-1)- X travel

1,800 mm

(70.87 in)- Y travel

1,300 mm

(51.18 in)- Z travel

1,800 mm

(70.87 in)

Description

Moving crossbeam with double column design

One-piece H-shaped column design

Y-axis adopt "symmetrical dual-drive" design

European mechanical milling head with high torque up to 1,200 Nm

European torque motor drive rotary table

Friendly operation interface

A. European mechanical milling head with high-torque up to 1,200Nm

B. X-axis moving crossbeam structure design

C. One-piece H shaped column design

D. Y-axis adopt "symmerical dual-drive" design

E. European torque motor drive rotary table

X-axis

1. Double column structure provides powerful support while high speed and high acceleration/deceleration machining, and to ensure high rigidity and high precision.

2. X axis crossbeam is supported by wide span (1,000mm) heavy-duty linear guideways to ensure the heavy load and high rigidity while machining.

Y-axis

1. Symmetrical Dual Drive" is with dual servo motor driven 2 ball-screws to ensure the machining efficiency and long lasting of ball-screw.

2. With powerful support of H-shaped column and 2 heavy-duty roller linear guideway on each column is to ensure the best movement and high rigidity of moving crossbeam, as well as maintain accuracy and rigidity while cutting.

3. Y-axis equips 4 heavy-duty roller linear guideway and adopts with 8 heavy-duty roller linear guideway slider, providing milling head the best rigidity.

Z-axis

1. High rigidity one-piece base with rotary table that is designed wide span (1,000mm) supported by heavy-duty linear guideway and 8 heavy-duty roller linear guideway slider to ensure the heavy load and high rigidity.

X/Y/Z-axis

4 HEIDENHAIN linear scale are installed X/Z axis each 1 and Y-axis 2

Catalogs

No catalogs are available for this product.

See all of KEN ICHI MACHINE CO., LTD‘s catalogsRelated Searches

- Machining machine

- Aeronautic machining center

- 5-axis machining center

- CNC machining center

- Horizontal machining center

- Vertical machining center

- Machining center for the aerospace industry

- Gantry machining center

- Machining center with swiveling spindle

- Machining center with moving table

- Double-column machining center

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.