- Products

- Catalogs

- News & Trends

- Exhibitions

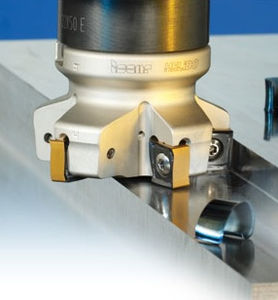

Carbide milling tool EPN-Fdiamondfor metal

Add to favorites

Compare this product

Characteristics

- Material

- carbide, diamond

- Dispensed product

- for metal

- Diameter

Max.: 25 mm

(0.984 in)Min.: 6 mm

(0.236 in)

Description

New solid endmills have a special edge configuration for machining CFRP composite parts and honeycomb.

The increased popularity of composites in aerospace applications creates new challenges for metal cutting shops. One of these substances, Carbon Fiber Reinforced Plastic (CFRP), can be especially difficult to machine.

These materials are extremely abrasive and difficult to machine, as a result of the different physical properties of the materials used in the layers that make these composites hard, tough and strong. Due to the harsh cutting environment, tool life can be very short when machining CFRP composites.

The impact of the cutting edge fractures the hard carbon fibers, instead of shearing material away. This process causes the cutting edge considerable abrasion that can lead to rapid wear.

In order to successfully machine CFRP, ISCAR offers hard, sharp solid-carbide tools made from grade IC02 which can be supplied on request with long-lasting diamond coating (IC2018).

EPN-F Endmill Features

Fine pitch - 10 and 12 flute endmills

Unique flute profile provides good surface finish

In most cases, eliminates CFRP fiber breakout

Reduces delamination

Decreases cutting forces

Available in diameter 3-12 mm

Available in IC02 uncoated or diamond coated on request

Related Searches

- Aeronautic milling tool

- Metal milling cutter

- Carbide milling tool

- Aeronautic drill bit

- Solid drill bit

- Metal drill bit

- Milling tool for the aerospace industry

- Carbide drill bit

- Diamond milling tool

- Aluminum milling tool

- Insert milling tool

- Steel milling tool

- Aeronautic reamer

- Reamer

- Cylindrical milling cutter

- Aeronautic cutting insert

- Cutting insert

- Composite cutting insert

- Metal reamer

- Steel drill bit

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.