- Production - Materials - Metrology

- Test equipment - Metrology

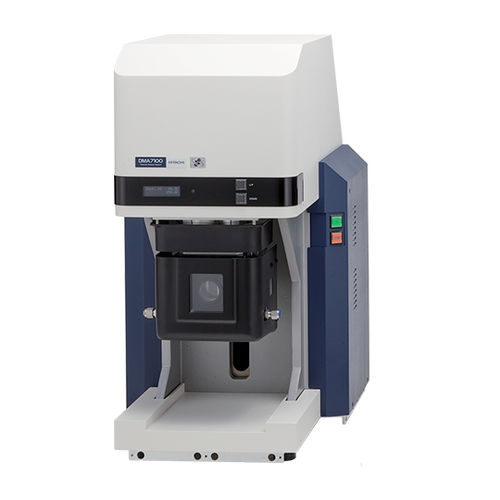

- Material analyzer

- Hitachi High-Tech Analytical Science

Signal analyzer NEXTA® DMA200materialnoiseliquid

Add to favorites

Compare this product

fo_shop_gate_exact_title

Characteristics

- Other characteristics

- signal, material, noise, liquid

- Configuration

- benchtop

- Other characteristics

- for aeronautics

Description

The Dynamic Mechanical Analysis (DMA) technique enhances sensitivity in measuring glass transition, material stiffness and the impact of frequency on mechanical traits. It gauges the viscoelastic properties of materials. Reliable for product engineers in applied research and materials development, DMA analyzers offer precise measurements of mechanical properties for simple and complex materials.

Our DMA features an innovative Real View® camera system that offers real-time observation during measurements, aiding in understanding unexpected behaviors like sample damage or color shifts. It also ensures the verification of data point reliability, even after the measurement process is concluded. And, with its exceptionally wide measurement range and rapid electronic response, our DMA is the perfect tool for assessing both stiff and soft samples, while also capturing rapid modulus changes.

Utilize the 20N force range for analyzing stiff materials, ideal for carbon fiber composites and other high-performance materials.

Access a wide applied force range with 5E-6N resolution and minimal output signal noise, enabling the detection and resolution of even the smallest transitions.

Choose from air, liquid nitrogen (LN2) or electrical gas cooling options; electrical gas cooling relies on power, eliminating external resources, while our LN2 cooling platform reduces its consumption by up to 30%.

Easily validate your results during or after analysis with the Lissajous monitor function, ensuring confidence in your results.

The Real View system, various measuring modes, rapid modulus change detection and advanced analysis provide versatile insights for research.

VIDEO

Catalogs

No catalogs are available for this product.

See all of Hitachi High-Tech Analytical Science‘s catalogsOther Hitachi High-Tech Analytical Science products

Thermal Analyzers

Related Searches

- HITACHI analyzer

- HITACHI aeronautic analyzer

- HITACHI benchtop analyzer

- HITACHI aeronautic thickness gauge

- HITACHI thickness gauge

- HITACHI material analyzer

- HITACHI coating thickness gauge

- HITACHI XRF analyzer

- Portable analyzer

- Signal analyzer

- HITACHI NDT thickness gauge

- Noise analyzer

- HITACHI eddy current thickness gauge

- Thickness gauge for the aerospace industry

- Digital display thickness gauge

- Magnetic thickness gauge

- Metal analyzer

- Laser analyzer

- Liquid analyzer

- Magnetic induction thickness gauge

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.