- Software - Simulation

- Software

- Process software

- HGL Dynamics

Management software Trim Balance Proprocessfor aeronautics

Add to favorites

Compare this product

Characteristics

- Function

- management, process

- Applications

- for aeronautics

Description

Anyone who has to maintain rotating machinery will sooner or later be faced with a unit that needs to be trim balanced. Failing to ensure equipment is properly balanced will inevitably lead to premature failure and costly delays to production.

Traditionally it was necessary to have staff with considerable experience and training to carry out the trim balancing operations OR to call on the services of a specialist contractor.

HGL Dynamics has used its in-house experience in the rotating machinery industry and its specialist team of software developers to produce an exciting software package that allows almost anyone to successfully carry out trim balancing operations on a wide range of machinery.

HGL’s Trim Balance Pro software is a standalone software package supplied on a single optical media containing the software application and product documentation.

For a machine to be trim balanced, the minimum requirement is that it must have at least one vibration transducer (either an accelerometer or a proximity / displacement probe) and a once per revolution signal to act as a phase reference. You will also require an instrument that can resolve the magnitude of the vibration and the phase of the signal relative to the once per revolution signal. HGL have a wide range of suitable units ranging from 4 to 32 channels, including our ultra-portable Firefly, or you can use an instrument you already own.

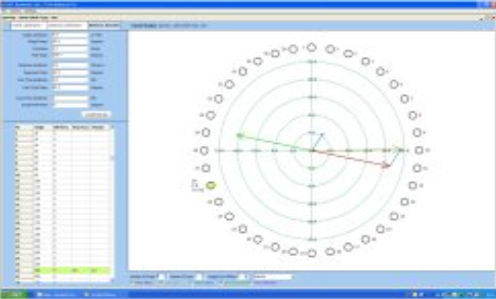

HGL Trim Balance Pro has two operational modes: a Wizard mode that guides even the most unfamiliar operator through the process to a successful outcome, and an expert mode that provides more data and printable polar diagrams along the way.

Catalogs

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.