Aluminum honeycomb HexWeb® Acousti-Cap®for the aerospace industry

Add to favorites

Compare this product

fo_shop_gate_exact_title

Characteristics

- Material

- aluminum

- Applications

- for the aerospace industry

Description

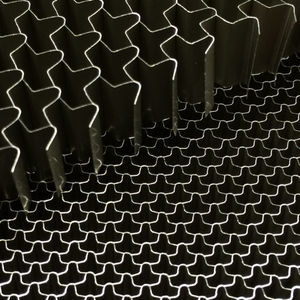

JEC Innovation Award winning HexWeb® Acousti-Cap® sound attenuating honeycomb enables aircraft engine designers to achieve superior acoustical performance, including dramatic noise reduction during takeoff and landing without a structural weight penalty. This marks an improvement on current technology which requires tradeoffs between weight and noise reduction.

HexWeb® Acousti-Cap® non-metallic honeycomb consists of permeable cap material embedded into a honeycomb core to create an acoustic septum. Customers specify the flow resistance characteristics, overall core thickness, and number of caps in a cell and insertion depth. The result is a product tuned to their acoustic requirements.

HexWeb® Acousti-Cap® honeycomb is used by GE and Rolls-Royce to save weight and reduce engine noise by up to 30%. The GENX-2B engine, with HexWeb® Acousti-Cap® honeycomb, powered the first flight of the new Boeing 747-8 and is also used in the LEAP engine on the latest Boeing 737MAX.

HexWeb® Acousti-Cap® honeycomb provides marked noise reduction in aircraft engines which means:

Lower landing fees at airports – a recurring cost saving

Increased fleet flexibility

Improved cabin comfort

Reduction in other acoustic treatments, resulting in lower weight and costs

“The use of Hexcel’s AcoustiCap® and HexPly® carbon fiber prepreg in combination with the AleniaAermacchi patented process has resulted in the design and manufacture of a state-of-the-art acoustic panel.” -- AleniaAermacchi Senior Design Engineer.

Catalogs

HexWeb® Acousti-CAP®

4 Pages

Related Searches

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.