- Software - Simulation

- Software

- Measurement software

- HEXAGON METROLOGY SAS

Reporting software controlqualitymeasurement

Add to favorites

Compare this product

Characteristics

- Function

- reporting, control, quality, measurement, CAD, manufacturing, programming, automation

- Applications

- for aeronautics

- Type

- 3D

Description

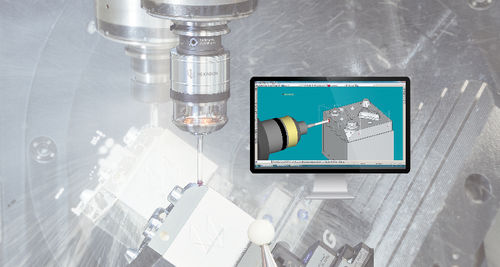

3D Form Inspect is the proven solution for your success. Measuring and quality control on the machine tool is gaining increasing importance in progressive manufacturing plants. This software enables quick, easy measuring and logging of important geometries and shapes on all sides and with all axes directly on the machine tool. This saves time, provides safety, and enhances quality.

Easy measuring and logging directly in the same clamping

3D Form Inspect allows you to easily and quickly measure and log ruled geometries and forms on all sides with all axes directly on the machine tool. This offers major benefits, particularly in mould and die, as well as in the aerospace industry. 3D Form Inspect saves time, offers improved safety during production and increases quality.

• Intuitive handling and creation of complex measuring tasks without prior programming knowledge require

• Reliable measuring results thanks to RTC – Real Time Calibration

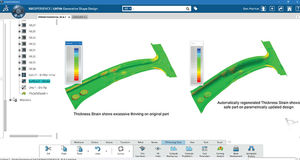

• Easy, safe control of freeform surfaces and ruled geometries on 3- to 5-axis machines

• Easy post-processing of critical surfaces using Best Fit adjustment on completed workpieces

• Automation option with 3DFI JobMaster.

Easy handling

• Self-explanatory user interface for easiest handling

• Practice-oriented measuring functions, designed for the machine operator

• Touch probe collision detection gives safety

• Automatic transmission of measuring programs and results

Universally applicable

• Extensive import filters for CAD surface data

• Available for almost all CNC controls

Save costs - increase your competitiveness

• Optimum definition of workpiece zero point in relation to workpiece contour

Catalogs

No catalogs are available for this product.

See all of HEXAGON METROLOGY SAS‘s catalogsRelated Searches

- Software for the aerospace industry

- Real-time software

- Process software

- Maintenance software

- 3D software

- Online software

- 2D software

- Measurement software

- Web-based software

- Automated software

- Server software

- Machining software

- Calculation software

- Data collection software

- Inspection software

- Web browser software

- CFD software

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.