- Software - Simulation

- Software

- Measurement software

- HEXAGON METROLOGY SAS

Control software HxGN NC Gagemeasurementmanufacturingprogramming

Add to favorites

Compare this product

Characteristics

- Function

- control, measurement, manufacturing, programming, inspection, process, machining

- Applications

- for aeronautics

- Type

- 2D, automated

Description

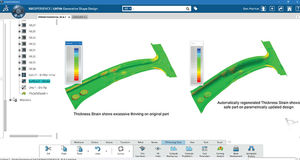

NC Gage revolutionises probing on machine tools. The simple use, and innovative “Teach-in” process allow a user to create gauging programs without previous programming knowledge, even on 5 axis machines and multi-tasking machines.

HxGN NC Gage uses the same PTB-Certified algorithms used by coordinate measuring machines. This allows NC Gage to bring the highest precision to machines, and to establish trust in manufacturing processes. Measurement is not limited to specific numbers of points or 2D features. Also distances, angles between features and basic GD&T functions are available.

HxGN NC Gage is available on Windows PC or embedded in the control panel. It is currently compatible with controls from Makino, Mazak, Okuma, DMG Mori, Mitsubishi, Fanuc and others.

Features & benefits

Advanced measuring capabilities

Use any number of functions for measurement and automatic part setup. For instance: Bores, Contructed Points, or Mid-points

Simple use with unique Teach-In function

Thanks to the dialog-based interactive teach-in method, the machine user can easily create measurement cycles without any macro programming knowledge.

Measuring on 5-axis machines (Option)

Effective use of 5 axis machines requires quick measurement and setup of workpieces. This is easier than ever with HxGN NC Gage, regardless of which 5 axis kinematic-type is used for machining and measuring.

Measuring on multi-tasking machines

NC Gage is designed for use on modern multi-tasking machines and supporting challenging machining tasks. Special functions simplify adding fully automated gauging, setup and inspection to multi-spindle processes.

CheckSet5 – Keeping 5-axis kinematics in check (Option)

Catalogs

No catalogs are available for this product.

See all of HEXAGON METROLOGY SAS‘s catalogsRelated Searches

- Software for the aerospace industry

- Real-time software

- Process software

- Maintenance software

- 3D software

- Online software

- 2D software

- Measurement software

- Web-based software

- Automated software

- Server software

- Machining software

- Calculation software

- Data collection software

- Inspection software

- Web browser software

- CFD software

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.