- Software - Simulation

- Software

- Measurement software

- HEXAGON METROLOGY SAS

Server software I++ SimulatormeasurementCADsimulation

Add to favorites

Compare this product

Characteristics

- Function

- server, measurement, CAD, simulation, monitoring, programming, process

- Applications

- for aeronautics

Description

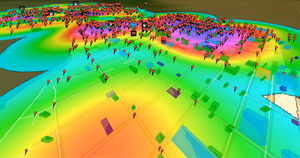

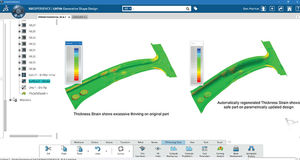

The I++ Simulator option is a stand-alone software package for the simulation of the complete measuring process. Realistic and comprehensive collision monitoring can only be carried out by visualising the complete process (machine, sensor, tool changers, tools, fixture and part).

Use of the I++ DME standards

The I++ Simulator is based on the independant I++ DME interface. As such, the I++ Simulator operates as a I++ server and machine in one software package - independent of the metrology software. The I++ Simulator can be used with every I++-conform metrology software(I++ client).

Application

The I++ Simulator can be used to simulate existing measurement programs as well as creating new ones using teach-in or off-line methods such as CAD. All without machine downtime. No additional know-how is required; reality merges with virtual reality to create the impression of sitting in front of a machine. The gamepad replaces the jog box for moving the machine and taking points manually.

Moreover, the I++ Simulator is the ideal training tool. All aspects of coordinate metrology can be practiced offline, without damaging a real machine due to "real" collisions. Cost effective, on-going, training increases the capabilities and qualifications of individual employees without tying up expensive machine time.

Features & Benefits

Existing QUINDOS parts are 100% compatible

Programs from other I++ DME - compatible measuring softwares can also run in the simulator

Collision and simulation TeachIn programming utilising a conventional gamepad

Selection of machines (Hexagon Metrology, Wenzel, Zeiss, etc.)

Comprehensive tool tip libraries (Hexagon Metrology, Renishaw, Zeiss)

Catalogs

No catalogs are available for this product.

See all of HEXAGON METROLOGY SAS‘s catalogsRelated Searches

- Software for the aerospace industry

- Real-time software

- Process software

- Maintenance software

- 3D software

- Online software

- 2D software

- Measurement software

- Web-based software

- Automated software

- Server software

- Machining software

- Calculation software

- Data collection software

- Inspection software

- Web browser software

- CFD software

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.