- Software - Simulation

- Software

- Process software

- HEXAGON METROLOGY SAS

Simulation software HxGN planningqualityanalysis

Add to favorites

Compare this product

fo_shop_gate_exact_title

Characteristics

- Function

- process, planning, quality, analysis, design, CAD, manufacturing, simulation

- Applications

- for aeronautics

- Type

- 3D

Description

Virtual manufacturing simulation software harnesses powerful simulations and innovation to drive sustainable and efficient manufacturing processes, enabling manufacturers to achieve ‘Shift to Zero’.

Software Solutions for optimising processes and manufacturing efficiently

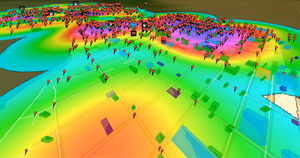

Create reliable and accurate virtual manufacturing realities with a wide range of simulation software, including metal forming, assembly & joining, and additive manufacturing, aiming at optimising manufacturing processes during design.

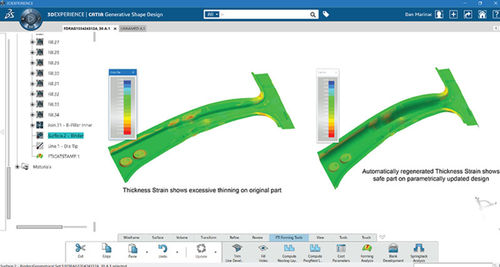

Perform quick feasibility studies of sheet metal parts during the design phase to enhance designs for manufacturability (DFM) quality. The forming solution streamlines the forming process by eliminating re-work and reducing engineering changes after part design release. It also provides fast and accurate estimations of blank shapes and springback for sheet metal components, improving the part’s overall efficiency.

Cost Engineering

Define target costs early in the design phase through a realistic stamping cost engineering analysis. Manufacturers and engineers can effectively derive should-cost scenarios, improve overall material utilisation, and reduce vehicle weight and tooling development time.

Process Planning / Technical Planning

Develop a detailed process plan for quoting & estimating from your 3D CAD (Computer Aided Design) design. Generate realistic images for each die operation. This scientific and data-driven approach empowers cost and design engineers to derive fast and accurate quoting and estimating processes and technical planning.

VIDEO

Catalogs

No catalogs are available for this product.

See all of HEXAGON METROLOGY SAS‘s catalogsRelated Searches

- Software for the aerospace industry

- Real-time software

- Process software

- Maintenance software

- 3D software

- Online software

- 2D software

- Measurement software

- Web-based software

- Automated software

- Server software

- Machining software

- Calculation software

- Data collection software

- Inspection software

- Web browser software

- CFD software

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.