- Software - Simulation

- Software

- Measurement software

- HEXAGON METROLOGY SAS

Reporting software 3DFI JobMaster controlqualitymeasurement

Add to favorites

Compare this product

Characteristics

- Function

- reporting, control, quality, measurement, manufacturing, automation

- Applications

- for aeronautics

- Type

- 3D, automated

Description

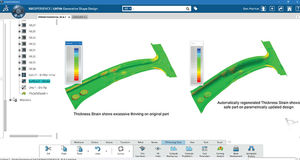

Flexibility with low production costs and high quality is the “magic triangle” for every company in the aerospace or tool and die making industries. Certainly, quality control must provide useful support as part of the whole system. As a driver of innovation in the field of machine tool measurement, Hexagon Manufacturing Intelligence has created a software module for 3D Form Inspect which increases your productivity, reduces production costs and guarantees high flexibility – together this is Connected Probing.

Measuring, Reporting and Best-Fit – Automation for 3D Form Inspect

3DFI JobMaster manages workpieces on the machine tool, providing access to the correct measuring and Best Fit operations, and allowing full operation and reporting in automatic mode. This considerably simplifies production during the night shift.

JobMaster for highest productivity

Fully automated measurement solution

Unmanned operation with Best Fit compensation and reporting

Automates measurement and reporting

Automatic best-fit operations even on different components

Ideal for machines with pallet system or automatic loading

Increasing the efficiency of production cells

Catalogs

No catalogs are available for this product.

See all of HEXAGON METROLOGY SAS‘s catalogsRelated Searches

- Software for the aerospace industry

- Real-time software

- Process software

- Maintenance software

- 3D software

- Online software

- 2D software

- Measurement software

- Web-based software

- Automated software

- Server software

- Machining software

- Calculation software

- Data collection software

- Inspection software

- Web browser software

- CFD software

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.