- Software - Simulation

- Software

- Measurement software

- HEXAGON METROLOGY SAS

Server software Q-DAS RTMmeasurementdesignmanufacturing

Add to favorites

Compare this product

Characteristics

- Function

- server, measurement, design, manufacturing, monitoring, process

- Applications

- for aeronautics

- Type

- real-time, automated

- Operating system

- web browser

Description

RTM helps machine operators to monitor the manufacturing process. The operator can visualise the manufacturing process for a single machine using a direct database connection.

Real-time monitoring

The operator can visualise the production process for a single machine using a direct database connection. The simple and intuitive setup wizard makes it easier to set up each new monitoring action. Automated parts replacement completes the functionality.

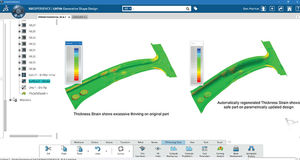

Q-DAS RTM (Real Time Monitoring) software screenshot

A single installation, accessible from anywhere

Q-DAS RTM is one of the new Q-DAS web products, as is Q-DAS qs-STAT Web. What they all have in common is that they can be launched via web browser and by using the new Q-DAS Web Launcher. This means that a conventional client installation is no longer necessary.

A single installation on the server is all it takes, since the necessary client installation

Monitoring the manufacturing process

Use RTM to monitor the manufacturing process directly from the database

RTM is intended to make the monitoring of a machine as easy as possible for the user and to monitor the production regardless of the part or parts currently produced on the machine (and thus the process). Once set up, RTM works fully automatically and monitors the process; parts are even replaced automatically. This makes it easier for the machine operator or the user to monitor the manufacturing process without further assistance.

The indicator design immediately signals to the operator that something was wrong with the last measurement. The tool uses a simple two-state system, green or red, to indicate the status.

VIDEO

Catalogs

No catalogs are available for this product.

See all of HEXAGON METROLOGY SAS‘s catalogsRelated Searches

- Software for the aerospace industry

- Real-time software

- Process software

- Maintenance software

- 3D software

- Online software

- 2D software

- Measurement software

- Web-based software

- Automated software

- Server software

- Machining software

- Calculation software

- Data collection software

- Inspection software

- Web browser software

- CFD software

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.