- Software - Simulation

- Software

- Aeronautic software

- HEXAGON METROLOGY SAS

Management software SpatialAnalyzerERPqualitymanufacturing

Add to favorites

Compare this product

Characteristics

- Function

- management, ERP, quality, manufacturing

- Applications

- for aeronautics

Description

What is SpatialAnalyzer?

Discover SpatialAnalyzer – powerful, traceable, easy-to-use metrology and analysis software for large-scale applications.

What is SpatialAnalyzer?

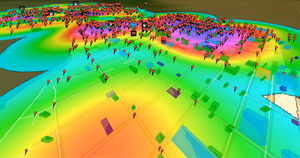

SpatialAnalyzer is the premier portable metrology software solution for large-scale applications.

SpatialAnalyzer in action

Discover the capabilities of SpatialAnalyzer in this video

What's new in SpatialAnalyzer?

Explore the latest features in your version of SpatialAnalyzer.

Why choose SpatialAnalyzer?

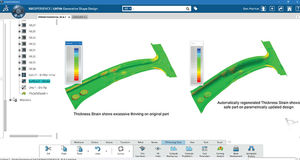

Learn how SpatialAnalyzer can provide support for multiple portable metrology instruments, help with real-time build and virtual assembly, provide traceability of work, enables GD&T inspection, and make generating custom reports easy. SA addresses ASME and ISO standard GD&T requirements with support for native CAD annotations. With SA, inspecting parts, building, analyzing data, and automation complex operations to improve measurement and inspection efficiencies is easy.

Aerospace

Leica Laser Trackers & SpatialAnalyzer in Aerospace Manufacturing

The Determinate Assembly (DA) technique is used in aerospace assemblies. It requires drilling precise and matching hole patterns for fastening mating parts. The DA technique is critical to building large aerospace structures effectively as it allows for consistent and accurate assembly, and component alignment. Massive NC machines or large jigs are often used to achieve the required precision to drill DA hole patterns. These methods are both expensive and inflexible to changes in design and process. An alternate technique uses a robot on a rail using a large scale precision metrology system.

Catalogs

No catalogs are available for this product.

See all of HEXAGON METROLOGY SAS‘s catalogsRelated Searches

- Software for the aerospace industry

- Real-time software

- Process software

- Maintenance software

- 3D software

- Online software

- 2D software

- Measurement software

- Web-based software

- Automated software

- Server software

- Machining software

- Calculation software

- Data collection software

- Inspection software

- Web browser software

- CFD software

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.