- Products

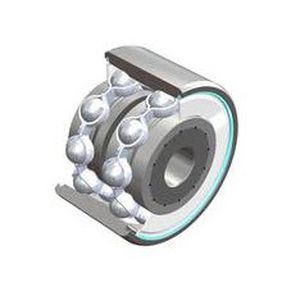

- Ball bearing bearing

- GRW Bearing

Ball bearing bearing radialaxialdeep groove

Add to favorites

Compare this product

Characteristics

- Rolling element

- ball bearing

- Configuration

- radial, axial, deep groove, single-row

- Material

- chrome steel, ceramic

- Other characteristics

- corrosion-resistant, high-precision, with cage, hybrid

Description

Single-row deep-groove ball bearings are suitable for use at both low and high speeds. They absorb radial and axial forces. They cannot be dismantled. (Electric motors, fans, encoders, flowmeters, etc.)

Single row deep-groove ball bearings consist of

An inner and an outer ring

A set of balls with cage and (usually) a layer of load-bearing lubricant

Optional covers or seals.

Application of a suitable lubricant will extend the service life of these ball bearings. GRW offers a range of over 400 different lubricants (oils and greases) from which we can select, based solely on your needs.

Materials and designs

In addition to our chromium steel, for 100Cr6 bearing rings, we also offer the stainless martensitic anti-friction SS (X65Cr13) and SV (X30CrMoN15-1) roller bearing steels. In our hybrid designs the balls are made of ceramic materials. We offer a standard two-part steel ribbon-type cage. Plastic cages in different materials and designs are also available. Non-slip covers are made of corrosion-resistant sheet steel, reinforced Perbunan (nitrile rubber) or fluorine rubber (FKM). Depending upon the design of the bearing, the sealing discs next to the inner ring are made from Teflon-coated glass fiber fabric, reinforced Perbunan (nitrile rubber) or fluorine rubber (FKM). Over 300 different lubricants can be configured based on application requirements.

Standard range and special formats

Our standard version deep-groove ball bearings are classified according to ISO or AFBMA. However, when special tolerances and special versions are required in lieu of a standard version, we can accommodate your specifications.

Catalogs

No catalogs are available for this product.

See all of GRW Bearing‘s catalogs*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.