- Production - Materials - Metrology

- Production machine

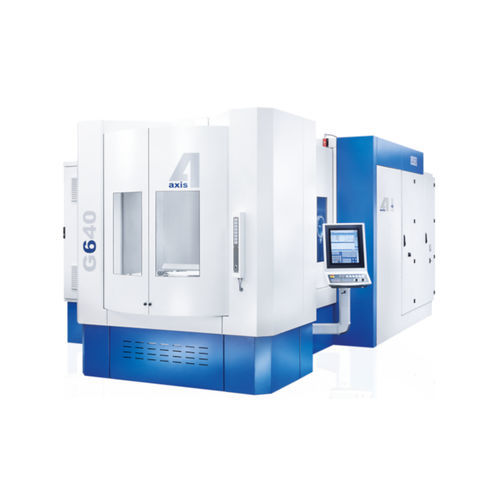

- 4-axis machining center

- GROB-WERKE GmbH & Co. KG

4-axis machining center G640universalfor aeronauticsCNC

Add to favorites

Compare this product

Characteristics

- Number of axes

- 4-axis

- Spindle orientation

- universal

- Applications

- for aeronautics

- Other characteristics

- CNC

- X travel

1,050 mm

(41.34 in)- Y travel

800 mm

(31.5 in)- Z travel

1,050 mm

(41.34 in)

Description

The 4-axis universal machining centers G440, G640 and G840 offer our customers a heavy-duty machine series, which at the same time guarantees robust and also optimal, dynamic processes.

High productivity, reliable components and a unique loadability characterize the 4-axis machine series. Thanks to extensive configuration options, our machining centers can be perfectly matched to the requirements of your production.

Your advantage at a glance

High productivity

Optimized availability

Maximum flexibility with weight loading of the pallet changer

Maintainable

Flexible applications

Maximum stability for the greatest volume machining

Optimized access

Round-the-clock service

Unique machine concept

Topology optimization

Topology optimization for a perfect combination between stability, damping and weight.

Motorized spindles

Thanks to the different types of motorized spindles (HSK, CAT, BT, SK, BIG-PLUS) you will have a bride range of possibilities to find the optimal solution for your machining.

Drive concept

Depending on the equipment, the drive concept is based on one ball screw drive arranged in the mass center or two symmetrically arranged ball screw drives in the Y-axis. The torque motor in the B' axis, which is already installed in the standard model, also enables a fast positioning movement with maximum precision.

Maximum stability

Optimally designed Tool Center Point (TCP) ensures extremely stable processes and high cutting performance.

Efficient machine cooling

Our efficient machine cooling concept includes the cooling of the power train, control cabinet, motorized spindle, rotary table and cutting fluid system,

VIDEO

Catalogs

No catalogs are available for this product.

See all of GROB-WERKE GmbH & Co. KG‘s catalogs*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.