- Production - Materials - Metrology

- Production machine

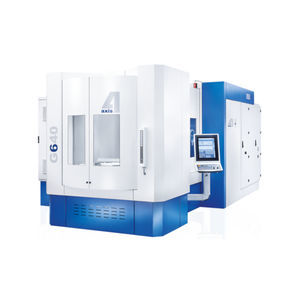

- 5-axis machining center

- GROB-WERKE GmbH & Co. KG

5-axis machining center G550horizontaluniversalfor aeronautics

Add to favorites

Compare this product

Characteristics

- Number of axes

- 5-axis

- Spindle orientation

- horizontal, universal

- Applications

- for aeronautics, cutting

- Other characteristics

- CNC

- X travel

800 mm

(31.5 in)- Y travel

1,020 mm

(40.16 in)- Z travel

970 mm

(38.19 in)

Description

The G550 machining center guarantees the best milling technology and extremely stable and precise cutting of practically all materials.

Benefit from the process reliability, efficiency and durability of our unique machine concept and trust in the GROB G550 for a dependable manufacturing facility.

The benefits at a glance

High productivity

Optimized availability

High visibility

Flexible applications

Maintainable

Compact design

Optimized access

Round-the-clock service

Unique machine concept

Horizontal spindle position

The horizontal spindle position permits the longest possible Z-travel path and optimum chip fall.

Maximum stability

The unique arrangement of the three linear axes minimizes the distance between the guides and the machining point (TCP), lending the machine considerable stability.

Tunnel concept

The tunnel concept allows the largest possible component – even in the case of with extremely long tools – to be swiveled and machined within the work area without collision.

Large swivel range

Three linear and two rotary axes permit 5-sided machining, as well as 5-axis simultaneous interpolation, with a swivel range of 230 degrees in the A'-axis and 360 degrees in the B'-axis.

VIDEO

Catalogs

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.