- Production - Materials - Metrology

- Production machine

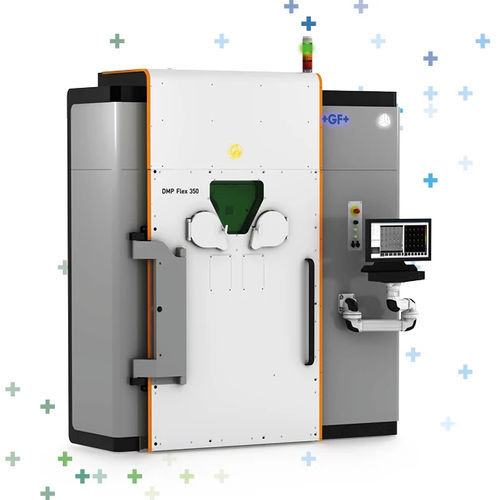

- Metal 3D printer

- GF Machining Solutions - Step Tec

Metal 3D printer DPM Flex/Factory 350FDMdesktopfor the aerospace industry

Add to favorites

Compare this product

Characteristics

- Printed material

- metal

- Heating technology

- FDM

- Other characteristics

- desktop

- Domain

- for the aerospace industry

- X travel

275 mm

(10.83 in)- Y travel

275 mm

(10.83 in)- Z travel

420 mm

(16.54 in)

Description

Robust, flexible metal 3D printer for 24/7 part production

The DMP Flex 350 enables more efficient production of very dense, pure metal parts and includes improved gas flow technology for improved uniform part quality across the entire build area. Flexible, high throughput, high repeatability metal 3D printer that generates high quality precision parts with maximum part size 275 x 275 x 420 mm from the most challenging alloys.

Maintain highly repeatable quality

The DMP Flex 350 delivers the purest atmosphere during printing: a consistently low oxygen environment (fewer than 25 parts per million). This solution ensures excellent microstructures and very high density and stable mechanical properties.

Benefit from high throughput

High throughput 3D metal printing is ensured by the solution’s fast, bidirectional material deposition. At the same time, users’ productivity is accelerated by high printer utilization and short changeover time.

Lower Total Cost of Ownership

An efficient factory is streamlined from end to end. With extensive experience in the production environment, our engineers have packaged their production workflow expertise into functional modules that enable maximum uptime and efficiency.

Available Materials

Ready-to-run metal alloys with thoroughly tested build parameters (Inconel, Titanium, Cobalt Chrome, Aluminium, Steel).

Build envelope size

Print large and high metal parts with our middle-size printer (*height inclusive of build plate).

O₂ level in the build chamber

Guarantees consistent powder quality for high quality parts.

VIDEO

Catalogs

No catalogs are available for this product.

See all of GF Machining Solutions - Step Tec‘s catalogsOther GF Machining Solutions - Step Tec products

Additive Manufacturing

Related Searches

- +GF+ aeronautic milling machine

- +GF+ milling machine

- +GF+ CNC milling machine

- Aeronautic cutting machine

- Cutting machine

- +GF+ multi-axis milling machine

- +GF+ vertical milling machine

- Metal cutting machine

- +GF+ 3D printer

- +GF+ 3D printer for the aerospace industry

- +GF+ metal 3D printer

- +GF+ 3-axis milling machine

- FFF 3D printer

- +GF+ milling machine for the aerospace industry

- CNC cutting machine

- Desktop 3D printer

- Laser cutting machine

- Glass cutting machine

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.