Control software HiMonitormanufacturingmonitoringprocess

Add to favorites

Compare this product

Characteristics

- Function

- control, manufacturing, monitoring, process, machining

- Applications

- for aeronautics

Description

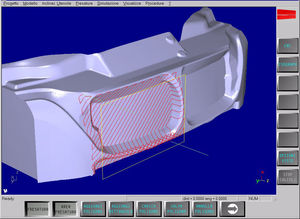

In order to improve the production process and to get the best efficiency out of milling machines, a user needs detailed information at hand of all the operations the machine has carried out. Detailed information includes actual working hours, interruptions/breakdowns, and the machine’s most important life events. Having this information available, the user can fully identify problems that may occur and carefully plan the most appropriate interventions to improve the machine efficiency.

To achieve this target and looking at the client’s requests, Fidia decided to develop two advanced modules: the Machine Monitoring System and the Monitoring system on WEB.

The former system identifies all the different machine and CNC activities registering them and then producing visual or printed reports, while the latter system allows the user to check out the machine status with a remote device such as a phone, a tablet or a PC. Working jointly, the modules allow for close workshop monitoring, accurate cost calculations, smooth manufacturing and extremely efficient interventions.

Machine Monitoring System: the workshop under control

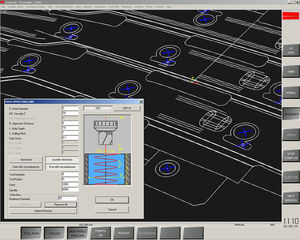

This module detects the following machine activities:

milling

waiting

fault

machine off

For each activity, the module records the timing. In addition, the module detects and records the most important events while the machine is running:

spindle start up/stop

refrigerating start up/stop

tool change

hand-wheel inputs (override) for spindle rotation and speed

feed hold

machine or control error

Reported events may be customized.

Timings and events can be reported by period, by machining or by project,

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.