Control software ViMill® programmingmachiningfor aeronautics

Add to favorites

Compare this product

Characteristics

- Function

- control, programming, machining

- Applications

- for aeronautics

Description

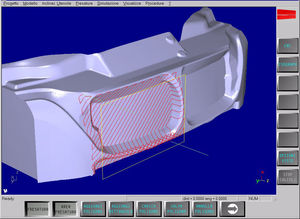

Over 40 years ago, Fidia has been the first one introducing the “look ahead” concept: the CNC “looks ahead” the programmed tool path in order to optimize acceleration and velocity of the machine. With ViMill®, this concept has been extended to safety. ViMill® is a software package, where the “look ahead” function has evolved to predicting any possible collision for safer machining.

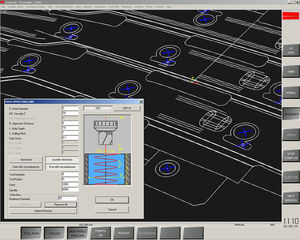

Being totally integrated in the Fidia numerical control, ViMill® can operate full time, covering any working condition of the machine: part program execution, manual data input, tool change cycle, measuring and alignment cycles and manual axis positioning by jog pushbutton or hand-wheel. When ViMill® is running, the Fidia CNC continuously checks out any possible collision between the moving parts of the machine, such as the milling head, tool, rotary table; and the fixed parts, such as the work-piece, clamps or table. Whenever a possible collision is detected, the control puts all the machine axes in the ‘hold’ condition and displays an appropriate message on the screen. The operator can then act accordingly and restart machining.

Why ViMill®?

There are several potential risk of collision:

complex part programs, especially for 5 axes machining, are becoming more and more difficult to check, leading to a higher risk of the tool or milling head crashing against the work piece

unattended machining may lead to dangerous working conditions

limited visibility can become a hazard when the operator cannot get so close to the milling tool

lack of communication between programming department and workshop may result in unexpected events

VIDEO

Catalogs

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.