- Software - Simulation

- Software

- Process software

- EOS GmbH Electro Optical Systems

Analysis software qualitymanufacturingmonitoring

Add to favorites

Compare this product

fo_shop_gate_exact_title

Characteristics

- Function

- quality, analysis, manufacturing, monitoring, automation, process

- Applications

- for aeronautics

- Type

- 3D

Description

The quality assurance and process monitoring features of EOSTATE Exposure OT — in a comprehensive package together with training, consulting and game-changing features like Smart Fusion.

Ensuring reliable production quality is important to all additive manufacturing (AM) projects and especially so to industrial metal 3D printing. The EOS Smart Monitoring* Plan is the ideal solution.

EOS Smart Monitoring includes all of the end-to-end monitoring capabilities critical for series production, and the cutting-edge automation of Smart Fusion makes a viable business case for more applications.

*requires an active EOS Build/Build+ Plan

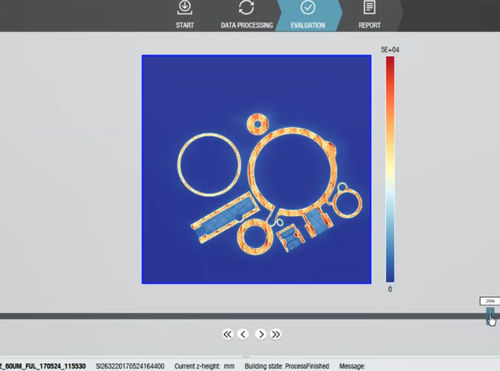

Exposure OT: 100% Insight

Smart Monitoring includes EOSTATE Exposure OT, an ingenious pairing of hardware and software by utilizing optical tomography for process insights.

High-Resolution Near-Infrared Camera

A high-resolution near-infrared camera records and measures the energy input in real time — regardless of part size. The long exposure time of the camera facilitates better analysis of the build's individual layers

A Toolbox to Determine Process Flaws

Based on analysis algorithms (uniquely adjustable to meet individual project requirements), EOSTATE Exposure OT provides a toolbox to determine process flaws.

This allows you to forgo destructive testing and is less expensive than other non-destructive testing methods, such as X-ray and CT scanning. Thus, you can eliminate the need for costly downstream quality assurance and can ultimately reduce your scrap rate and percentage of build failures.

Insights derived from EOSTATE Exposure OT are important for future production cycles and to speed up product development.

Catalogs

No catalogs are available for this product.

See all of EOS GmbH Electro Optical Systems‘s catalogsRelated Searches

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.