- Production - Materials - Metrology

- Materials - Semi-finished products

- Stainless steel for the aerospace industry

- EOS GmbH Electro Optical Systems

Powder stainless steel 316Laeronauticalfor the aerospace industry

Add to favorites

Compare this product

Characteristics

- Form

- powder

- Other characteristics

- aeronautical, for the aerospace industry

- Mechanical resistance

Min.: 410 MPa

Max.: 1,720 MPa

- Typical elongation

6 %, 13.5 %, 30 %, 34 %, 47 %

Description

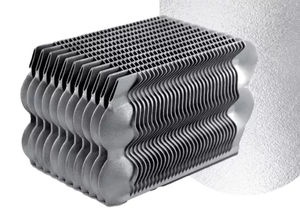

Stainless steel’s material characteristics make it ideal for a wide range of applications in medical, oil and gas, ship building, etc.

The stainless steel family of powders encompasses the 316L, 316L VPro, 254, SuperDuplex, 17-4PH, PH1 (15-5) and CX alloys. All these powders are designed and tested for use on EOS’ metal systems.

EOS stainless steel powders are shipped with an inspection certificate (according to EN 10204, Type 3.1) showing the results of the extensive QA testing. Only EOS StainlessSteel SuperDuplex is shipped with a material test report (according to EN 10204, Type 2.2) showing the results of the QA testing with regard to the chemical properties and particle size distribution.

EOS also offers a wide range of validated processes for each of the above materials. These offer the optimal combination of parameters (e.g. laser power, layer thickness, etc.) in order to ensure that the properties of the 3D printed part are consistently achieved.

Parts show a high level of corrosion resistance combined with high strength. This combination is ideal for the medical applications such as surgical instruments.

Highlights

Corrosion resistance and strength

Parts can be machined, shot-peened and polished in asbuilt or heat treated states

Solution annealing together with aging treatment are necessary in order to achieve proper hardness and mechanical properties (ASTM A564-13)

Chemical composition and part properties corresponding to 1.4542, UNS 17400 and ASTM A564M

Typical Applications

Acid and corrosion resistant engineering parts

Medical instruments (surgical tools, orthopedic instrumentation)

Other EOS GmbH Electro Optical Systems products

METAL MATERIALS

Related Searches

- Aeronautical stainless steel

- Stainless steel

- Titanium alloy

- Aeronautical titanium alloy

- Aluminum alloy

- Aeronautical aluminum alloy

- Stainless steel for the aerospace industry

- Aerospace titanium alloy

- Nickel alloy

- Nickel alloy for the aerospace industry

- Aluminum for the aerospace industry

- Bronze

- Aeronautical copper alloy

- Grade 2 titanium alloy

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.