- Software - Simulation

- Software

- Aeronautic software

- E-XSTREAM ENGINEERING

Data analysis software Digimat-FEsimulationmodelingfor aeronautics

Add to favorites

Compare this product

Characteristics

- Function

- data analysis, simulation, modeling

- Applications

- for aeronautics

Description

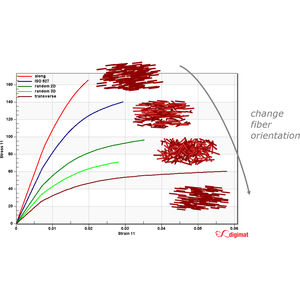

Digimat-FE is a Tool of Digimat software to compute composite materials' performances using the Finite Element homogenization method.

Digimat-FE generates realistic (stochastic) Representative Volume Elements (RVEs) for a large variety of material microstructures and can as well rely on external geometric microstructure description such as micro CT-scan or molecular dynamic results.

Based on material input and the microstructure definition, a finite element model is built and run. Various solvers are accessible to perform simulations including an embedded FEA solver, a Fast Fourier Transform solver and external solvers. The results of the FE analysis is post-processed in the sense of probabilistic distribution functions that give detailed insight into the RVE. Mean homogenized values are computed and can be used in subsequent FE analysis on the structural part level.

Digimat Finite Element technology is an End-to-end Tool for composite materials simulation:

A complete end-to-end solution has been implemented in Digimat®. It allows performing all the different steps needed to obtain a complete FE analysis - starting from the material data. For example for woven composites those steps are:

Extraction of the material data from the datasheet

Mean-field homogenization of the yarns

Generation of a geometry of a unit cell

Generation of a RVE

Voxelisation

FE model definition and application of periodic boundary conditions

Solving the FE analysis

Post-processing the outputs of the FE analysis

VIDEO

Catalogs

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.