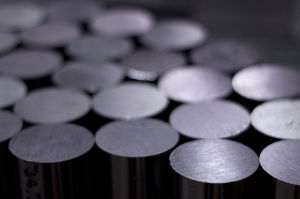

Ti 6246 titanium alloy rodTi-6Al-4VAMS 4981

Add to favorites

Compare this product

fo_shop_gate_exact_title

Characteristics

- Form

- rod

- Type

- Ti-6Al-4V, Ti 6246

- Other characteristics

- aerospace, AMS 4981

- Mechanical resistance

Max.: 1,240 MPa

Min.: 1,090 MPa

- Elasticity

Max.: 1,150 MPa

Min.: 1,020 MPa

- Typical elongation

Max.: 16 %

Min.: 13 %

Description

The main characteristics of 6246 are being light weight with exceptional strength and corrosion resistance. This high-performance alloy contains 6% aluminum and 4% zirconium along with titanium and trace elements.

The addition of aluminum and zirconium gives 6246 titanium increased strength compared to commercially pure titanium grades. It has an ultimate tensile strength around 1100 MPa, nearly double that of the Ti-6Al-4V alloy. Yet 6246 remains relatively light, with a density of 4.54 g/cm3.

Components made from 6246 can withstand tremendous mechanical stresses while remaining incredibly light.

6246 titanium offers great resistance to corrosion, the aluminum and vanadium stabilise the alloy against oxidation and prevent degradation.

Like other titanium alloys, 6246 is incredibly durable with a long service life. Products made from this alloy can withstand heavy wear and tear over years of use with minimal maintenance required. The material does not suffer from fatigue, galling, or seizing issues.

From a manufacturing perspective, 6246 titanium can be readily formed using standard metalworking techniques like machining, welding, and forming. However, the material is considered more difficult to process compared to other titanium grades due to its higher strength.

Whether used to construct aircraft components, high-performance automotive parts, or professional-grade sports gear, 6246 titanium delivers an unbeatable combination of strength, light weight, and corrosion resistance.

TYPICAL APPLICATIONS

RELATED SPECIFICATIONS

Compressor Discs and fan blades

Airframe components

Motor racing drivetrain components

Subsea sour service

AMS-T-9047

UNS R56260

Catalogs

No catalogs are available for this product.

See all of DYNAMIC METALS LTD‘s catalogsRelated Searches

- Aeronautical stainless steel

- Stainless steel

- Alloy steel

- Aeronautical alloy steel

- Plate stainless steel

- Titanium alloy

- Aeronautical titanium alloy

- Aluminum alloy

- Aeronautical aluminum alloy

- Steel alloy for the aerospace industry

- Stainless steel for the aerospace industry

- Aerospace titanium alloy

- Nickel alloy

- Nickel alloy for the aerospace industry

- Aluminum for the aerospace industry

- Titanium alloy rod

- Rod stainless steel

- Steel alloy rod

- Plate steel alloy

- Sheet aluminum alloy

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.