- Production - Materials - Metrology

- Production machine

- Dainichi Manufacturing Co., Ltd.

Aluminum machining stainless steelcomplex shapesISO 9001

Add to favorites

Compare this product

Characteristics

- Treated material

- aluminum, stainless steel

- Other characteristics

- complex shapes

- Certifications

- ISO 9001

Description

We have established integrated production system from 3D CAD modeling to creating programs by CAM to simulation. We manufacture impellers and propellers among many other products.

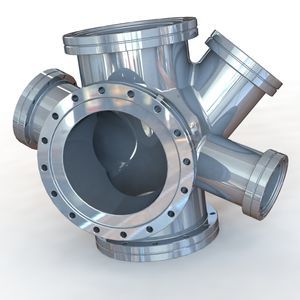

1. Three-Dimensional Processing and High-Efficiency Machining by Simultaneous 5-Axis Machining

Three-dimensional processing by simultaneous 5-axis machining such as impeller

Processing products strictly specified by geometric tolerance

Heat-resistant Ni-based alloys (Inconel, Hastelloy, etc.). Heat-resistant Co-based alloys, SUS (304, 316L, 310S, 630, 420J2, 440C, 431, etc.), AL, Ti, SC, FC, etc.

For quality assurance, we have put the inspection system in order with a 3D measuring machine in the temperature-controlled environment. It is possible to measure 3D shapes by scanning as well. We also use a 3D laser scanner to inspect 3D shaped products and shapes of casting and canning materials. Shapes are confirmed by comparing a 3D model and scanned data

2.Machining and Assembling of Measuring Instrument parts – Automatic Load Cell

Complete integrated product system from processing and supplying parts more than 500 to assembly of final products

Load cell processing (SUS630) included

SUS304, A5052, etc.

3.Machining and Assembling of Compressors Related Parts – Valves

From machining to assembling parts of the compressor’s intake valve adjustments for Kobe Steel, Ltd.

Load cell processing (SUS630) included

A5052, AC4C, etc.

4.Machining and Assembling Pumps – Gear Pump, etc.

From machining to assembling parts of pumps for large shipbuilding companies (gear pump, centrifugal pump, piston pump, etc.)

Load cell processing (SUS630) included

Other Dainichi Manufacturing Co., Ltd. products

Manufacturing

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.