- Production - Materials - Metrology

- Production machine

- Dainichi Manufacturing Co., Ltd.

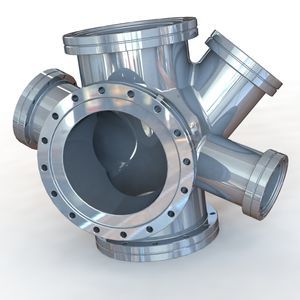

Elbow fitting machining

Add to favorites

Compare this product

Characteristics

- Part

- for elbow fittings

Description

1. Creating a 3D model

We create 3D CAD models based upon model information such as drawings, point clouds, data provided from our customers.

We support various data formats such as Solidworks and CATIA.

2. Creating a Machining Program

We generate the tool path for machining according to the 3D model by using CAM such as Mastercam.

We create a NC program by choosing the optimal cutting tool and machining angle based upon our extensive experience with many varieties of 5-axis machining.

3. Verifying a Program

We analyze the NC program derived from CAM by Vericut, the best simulation software on the market, and run an interference check for when multi-tasking machines are operated.

We achieve efficient processing by adjusting the machining path to be optimal for each machine.

4. Machining

We process with the verified NC program.

Even with the verified NC program, we find it necessary to check the sound and vibration of the cutting tool such as end mills at first, and we also make further adjustments depending upon processing conditions.

5. Inspecting the Finish Products

We perform inspections in accordance with our customers’ instructions.

We also offer contact measurement by the 3D measuring machine as well as inspect complicated shapes by laser beams.

High-Efficiency Machining for Complicated Workpiece Shapes Using the Latest 5-Axis Machine

For quality assurance, we have put the inspection system in order with a 3D measuring machine in the temperature-controlled environment. It is possible to measure 3D shapes by scanning as well.

Other Dainichi Manufacturing Co., Ltd. products

Manufacturing

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.