Control software VXtrackmeasurementmanufacturingmonitoring

Add to favorites

Compare this product

fo_shop_gate_exact_title

Characteristics

- Function

- control, measurement, manufacturing, monitoring, tracking, process

- Applications

- for aeronautics

- Type

- real-time, 3D

Description

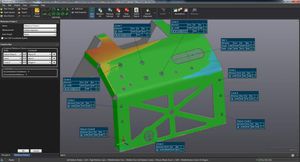

VXtrack is a dynamic tracking module that enables production and process engineers to obtain the position and orientation of multiple objects in time and space. Because measurements are taken simultaneously and accurately, VXtrack can easily control displacements, drive assembly processes, and measure deformations.

Thanks to the simplicity of optical tracking, VXtrack is ideal for numerous applications, including calibrating and guiding robots, monitoring complex assembly processes, and compensating for both machine tool positioning errors throughout manufacturing and deformations during testing.

USTOM INTERFACING

VXtrack is a customizable, easy-to-use dynamic control software that requires little training. Moreover, the interface of the 3D tracking software can be fully adapted to each client’s specific application and special needs.

PROCESS INTEGRATION

Easily integrated into client processes, VXtrack offers direct feedback, which means that decision-making becomes more effective, saving precious time for operators, who gain efficiency during the entire process.

COMPLETE TOOLKIT

Capable of tracking multiple objects simultaneously, the optical tracking software can measure a set of reflectors with 6 degrees of freedom (DOF) precision, capturing both the position and orientation.

Main features

Rate of up to 6,600 3D points per second

6 DOF measuring (position and orientation) of a rigid set of reflectors

Synchronous measurement of the reflector set

Measuring volume from 9.1 to 16.6 m3 (320 to 586 ft3)

One unique system for 3D inspection and 3D dynamic measurement

Real-time curve display in VXelements

Export to .csv format

Catalogs

No catalogs are available for this product.

See all of Creaform‘s catalogsExhibitions

Meet this supplier at the following exhibition(s):

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.