- Software - Simulation

- Software

- Viewer software

- CORETECHNOLOGIE

- Company

- Products

- Catalogs

- News & Trends

- Exhibitions

Viewer software Master CADmanufacturingfor aeronautics

Add to favorites

Compare this product

fo_shop_gate_exact_title

Characteristics

- Function

- viewer, CAD, manufacturing

- Applications

- for aeronautics

- Type

- 3D, 2D

- Other characteristics

- CATIA V5, Creo, NX

Description

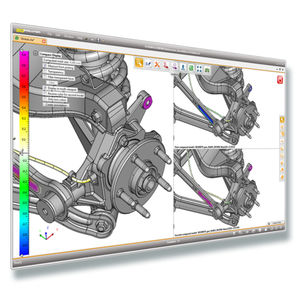

Native CAD models including dimensions and tolerances can be converted and also displayed with all specific functions of the Model Based Definition technology. The use of 3D-Master is reducing the need for 2D drawings to an absolute minimum, because in the 3D Model all production-relevant information is saved in so called views or captures.

Simplification of the Digital Manufacturing Process

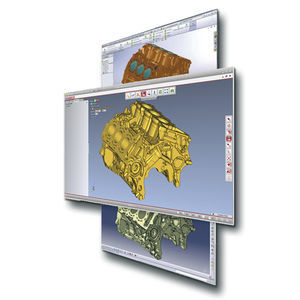

The 3D_Evolution software converts data from all CAD systems, including 3D master relevant formats such as Catia V5, NX, Creo as well as STEP AP 242 and JT. The viewer software 3D_Analyzer reads all current CAD data and also supports all 3D master specific functions.

To display all the information contained in the 2D drawing on a 3D model requires a special technology that combines tolerances, annotations, and dimensions in the views. By selecting a view, the model is aligned as previously defined by the designer and zoomed into a particular area. So only the dimensions chosen by the designer are shown.

In addition, sections can be saved in the views. As a result 3D master models eliminate the need for 2D drawings to produce the part. Also 3D Master models are easier to use and allow for a better comprehension compared to specific views created and printed out as 2D drawings. In addition usnig 3D Master there is only one data source needed to produce the parts which virtually eliminates errors and confusion often caused by different revisions of ambiguous 2D drawings.

Complete and Flexible Use

The 3D_Evolution MCAD converter suite transfers the graphical representation of the dimensions as well as the semantic i.e.

Catalogs

No catalogs are available for this product.

See all of CORETECHNOLOGIE‘s catalogsRelated Searches

- Software for the aerospace industry

- Process software

- 3D software

- Navigation software

- Test software

- 2D software

- Server software

- Calculation software

- Collaborative software

- Interoperability software

- NX software

- SolidWorks software

- Creo software

- Viewer software

- 3D printing software

- CATIA V5 software

- PLM software

- Additive manufacturing software

- Programming software library

- Software library

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.