- Software - Simulation

- Software

- PLM software

- CORETECHNOLOGIE

- Company

- Products

- Catalogs

- News & Trends

- Exhibitions

PLM software Partfindertestqualityanalysis

Add to favorites

Compare this product

Characteristics

- Function

- PLM, test, quality, analysis, CAD, calculation, manufacturing

- Applications

- for aeronautics, for 3D printing, for additive manufacturing

- Type

- 3D

- Other characteristics

- SolidWorks, Creo, NX

Description

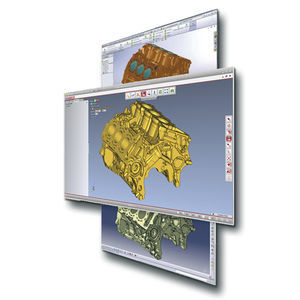

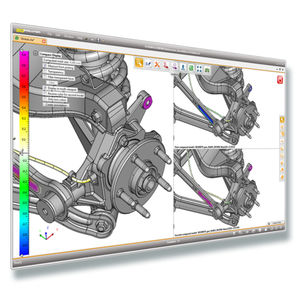

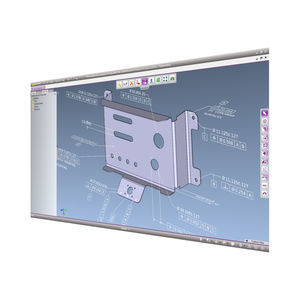

With the Partfinder CAD data of all common formats can be analysed, sorted and also converted automatically for different 3D printing processes and machine types.

The web interface of the Partfinder Manager allows flexible use in corporate networks and the native scripting language an easy integration into PLM systems. The multiprocessor calculation or cluster calculation allows an unrivaled fast analysis and/or conversion of large amounts of data.

3D_Evolution Partfinder comes with sophisticated interfaces for CATIA, NX, SOLIDWORKS, Creo, JT, STL, STEP, XT, Acis and many more enabeling a superfadst and highly precise batch conversion. The data can be saved for 3D printing in amf, 3mf and STL format. Sophisticated interfaces and analysis functions ensure that optimal quality and watertight" models are generated.

With the Partfinder, CAD data of all formats can be analyzed automatically with regard to the various additive manufacturing processes. The 3D models are geometrically analyzed and, in addition attributes contained in the data, e.g. Material information is used to classify each part.

All analyzes can be summarized in user definable test profiles and run in batch mode over a large number of models, so that even very large databases can be sorted automatically for Additive Manufacturing processes. Our native interfaces read out the attributes and metadata within milliseconds, enabling pre-sorting. Automatic 3D geometry analysis such as calculation of the bounding box, surfaces and volumes provides further important aspects for the automatic classification of the parts.

Catalogs

No catalogs are available for this product.

See all of CORETECHNOLOGIE‘s catalogsRelated Searches

- Software for the aerospace industry

- Process software

- 3D software

- Navigation software

- Test software

- 2D software

- Server software

- Calculation software

- Collaborative software

- Interoperability software

- NX software

- SolidWorks software

- Creo software

- 3D printing software

- CATIA V5 software

- Viewer software

- PLM software

- Additive manufacturing software

- Programming software library

- Software library

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.