- Software - Simulation

- Software

- Aeronautic software

- CORETECHNOLOGIE

- Company

- Products

- Catalogs

- News & Trends

- Exhibitions

Quality software VDA CADfor aeronautics3D

Add to favorites

Compare this product

Characteristics

- Function

- quality, CAD

- Applications

- for aeronautics

- Type

- 3D

Description

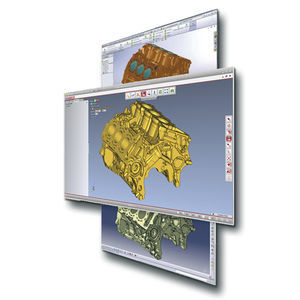

The certified 3D_Evolution© Quality Checker verifies all 3D geometries independent of the CAD format. It is the only conversion tool that is certified in accordance with SASIG/PDQ and VDA 4955/2 specifications.

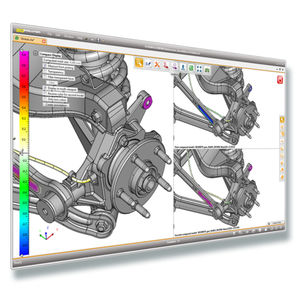

Failures on faces, surfaces, curves, and topology are accurately displayed on the model. The listing of error types in the checker’s tree structure allows for systematic selection of the geometries and error clearings. 3D_Evolution also has specific automatic healing and interactive clean-up functions for VDA-check-related errors, such as twisted faces, mini-faces and many others.

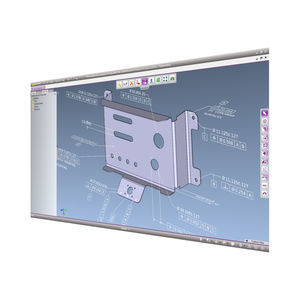

Depending upon the application and/ or customer requirements, testing profiles containing the relevant testing criteria can be saved. The result conforms with SASIG/PDQ and VDA 4955/2 specifications and can be saved in an HTML format. Similar to all other modules, the quality checker can be applied for individual parts or assemblies and runs also in batch mode.

This tool has been developed in close collaboration with the aerospace industry to validate CAD data for Long-Term Archival and Retrieval (LOTAR).

Based on the Geometric Validation Properties (GVP) values written in the STEP AP 242 files by the CAD system generating the 3D models the data will be read and checked by the independent 3D_Evolution kernel validating these values. Property values that differ from the calculated ones in a given tolerance will be indicated. Examples for these GVP are:

• Geometric, e.g., volume, surface, centroid, and COPS

• Assembly, e.g., number of children and solid centroids

• PMI, e.g., polyline curve length comparison

• Tessellation, e.g., centroid and surface area

Catalogs

No catalogs are available for this product.

See all of CORETECHNOLOGIE‘s catalogsRelated Searches

- Software for the aerospace industry

- Process software

- 3D software

- Navigation software

- Test software

- 2D software

- Server software

- Calculation software

- Collaborative software

- Interoperability software

- NX software

- SolidWorks software

- Creo software

- 3D printing software

- CATIA V5 software

- Viewer software

- PLM software

- Additive manufacturing software

- Programming software library

- Software library

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.