- Aircraft interiors

- Interior equipment

- Acrylic aircraft canopy

- Control Logistics Inc.

- Products

- Catalogs

- News & Trends

- Exhibitions

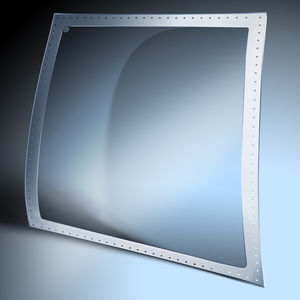

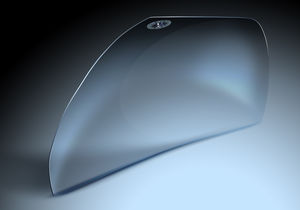

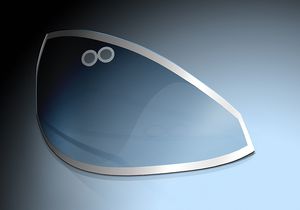

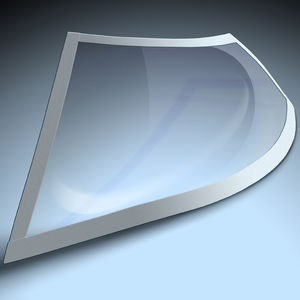

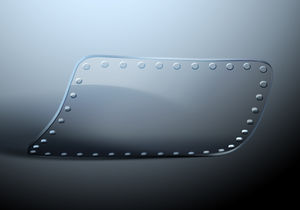

Airliner aircraft canopy A/T-37acrylicpolycarbonatebirdstrike resistant

Add to favorites

Compare this product

Characteristics

- Applications

- for airliners

- Material

- acrylic, polycarbonate

- Other characteristics

- birdstrike resistant

Description

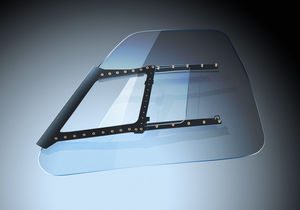

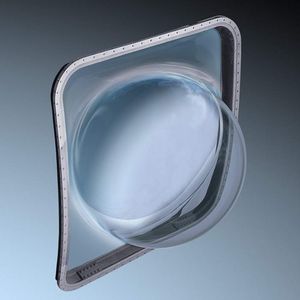

We specialize in advanced thermopolymer formations in stretched acrylic, cast acrylic and polycarbonate, always with minimal optical distortion and aberration, such as this example for the polycarbonate Cessna AT-37 Jet Trainer canopy. CLI can also offer forms in fiberglass laminate for applications such as window edgings.

EXPERIENCE

Our enterprise possesses comprehensive experience employing the latest and most advanced techniques within the industry, to achieve precise contour control, creating the very highest quality products for strength and durability.

TECHNICAL EXPERTISE

Within the transparency industry, our specialty is working with bi-axially stretched acrylics, (MIL-PRF-25690) ― a stronger, crack propagation resistant acrylic; cast acrylics (MIL-PRF-8184, and MIL-PRF-5425), and polycarbonate for products requiring very high impact resitance.

CLI also employs various industry standard techniques such as drape forming, vacuum forming, wet forming, and blow forming, to achieve precise control of window contours, yet always maintaining defect and distortion free optics.

FLEXIBILITY TO YOUR EXACT REQUIREMENTS

We are also capable to form products on customer supplied tools, or able to assist you in the development of specific products and help you build new tools for complex forming applications.

CERTIFICATION

CLI holds a BSI AS9100 certificate in quality assurance and has received various accolades for its exceptional products and services. We are proud to benchmark our service on meeting, and often exceeding, customer requirements for both process controls and product inspection.

Related Searches

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.