- Production - Materials - Metrology

- Production machine

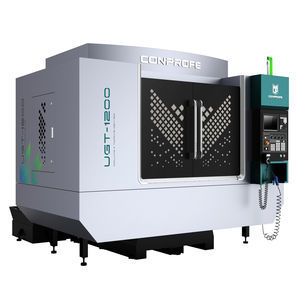

- 3-axis machining center

- Conprofe Technology Group Co., Ltd.

3-axis machining center UHT-1200verticalfor aeronauticsCNC

Add to favorites

Compare this product

Characteristics

- Number of axes

- 3-axis

- Spindle orientation

- vertical

- Applications

- for aeronautics

- Other characteristics

- CNC, rotating table

- Rotational speed

24,000 rpm, 30,000 rpm

(150,796 rad.min-1, 188,496 rad.min-1)- X travel

1,200 mm

(47.24 in)- Y travel

650 mm

(25.59 in)- Z travel

370 mm

(14.57 in)

Description

Suitable for machining precision parts made of hard-brittle materials (e.g. ceramic, sapphire, glass, silicon carbite etc.), carbon-fiber composites, superalloy (e.g. titanium alloy) and other hard-to-cut materials

Conprofe independently-developed Ultrasonic Machining System to solve issues in machining hard-to-cut materials

Optional Supercritical CO₂ or MQL Cooling System to realize clean machining

Three options for screw guides available to meet various machining requirements on hard-brittle materials and metal

Coolant-through BBT-30 Ultrasonic Spindle with max speed of 30,000rpm available

Various Tool Holding Capacity of tool magazine: 21T/26T/30T/36T/30T+14T

Positioning accuracy of 5μm and repeatability of 3μm

Spindle Nose to Table - mm - 180-550

Spindle Center to Z-Axis Cover - mm - 660

Worktable

Dimensions - mm - 1300×600

Max. Load - kg - 400

T-Slot (No. x Width x Distance) - pcs x mm x mm - 5x18x125

Spindle

Diameter - mm - Φ120

Motor Power (Rated) - kW - Y: 5.5 △: 7.5

Motor Torque (Rated) - Nm - Y: 8.73 △: 4.78

Spindle Taper - – - BT30

Ultrasonic - – - Standard

Minimum Quantity Lubrication (MQL) - – - /

Ultrasonic + MQL - – - /

Supercritical CO2 Spindle - – - /

VIDEO

Catalogs

No catalogs are available for this product.

See all of Conprofe Technology Group Co., Ltd.‘s catalogsOther Conprofe Technology Group Co., Ltd. products

Drilling & Milling Centers

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.