- Products

- Composite Integration Ltd

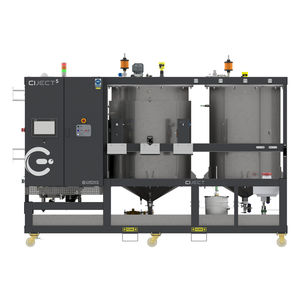

Injection machine for the aeronautical industry CIJECT 3

Add to favorites

Compare this product

Characteristics

- Application domain

- for the aeronautical industry

Description

CIJECT 3 is an advanced pressure-pot machine designed for pre-mixed or single component resin systems.

Originally developed for R&D and lab-scale processing, the CIJECT 3 has been developed further to meet the requirements of the aerospace and other hi-tech composite manufacturing industries. These machines allow different resin systems to be prepared (i.e. heated, mixed, degassed) and then dispensed, very accurately, without the need to clean and re-prime a mechanical pumping system.

Key Features & Benefits

Fully heated, PID controlled resin circuit to ensure process parameters are maintained.

Integrated vacuum pump to enable materials degassing and mould evacuation.

Closed loop PID pressure control. Automatic, regulated tank pressure to achieve desired pressure in mould.

Applications

R & D materials testing.

University laboratory projects.

High specification prototypes.

Catalogs

No catalogs are available for this product.

See all of Composite Integration Ltd‘s catalogs*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.