- Software - Simulation

- Software

- Aeronautic software

- Broetje-Automation

Simulation software SOUL RMOScontrolmanufacturingfor aeronautics

Add to favorites

Compare this product

Characteristics

- Function

- control, manufacturing, simulation

- Applications

- for aeronautics

- Type

- real-time, 3D

- Other characteristics

- CATIA V5

Description

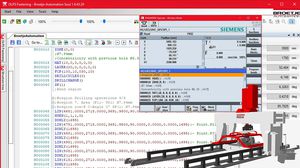

SOUL RMOS simulation software is an advanced solution for runtime protection of workpieces and machines. Its leading online path creation and collision detection capabilities reduce machine downtime and collisions, providing seamless path creation, simulation and execution on the machine. The software allows online machine movement simulation with virtual cameras and integrates the Siemens Virtual NC-Kernel for a most accurate virtual machine simulation.

The software provides real-time bi-directional machine-to-virtual twin synchronization and supports 3rd party machines. SOUL simulation software also comes with no annual license costs, making it a cost-effective solution for businesses looking to improve their manufacturing processes. Overall, SOUL simulation software is a powerful tool for manufacturers looking to improve the efficiency and safety of their operations.

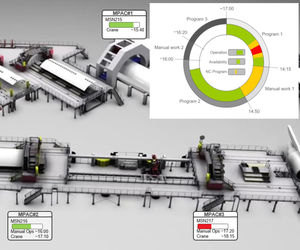

COLLISION FREE HANDLING OF LARGE STRUCTURES

In production, it is important to handle the components with care and foresight. In order to avoid damaging the large components during manual operation of the machine, SOUL RMOS provides support in the form of easy axis control, enabling complex entry and exit of the molds – without any risk of collision. Automatic travel routines and dynamic error control as well as collision check enable easy handling here.

Catalogs

No catalogs are available for this product.

See all of Broetje-Automation‘s catalogs*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.