- Products

- Catalogs

- News & Trends

- Exhibitions

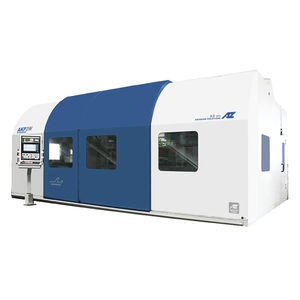

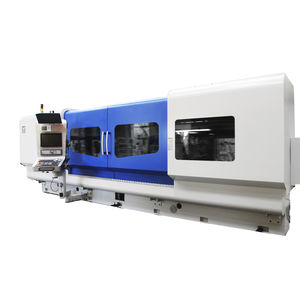

External cylindrical grinding machine RUG3000angularinternal cylindricalfor landing gear

Add to favorites

Compare this product

Characteristics

- Type

- external cylindrical, internal cylindrical, angular

- Other characteristics

- for the aerospace industry, for landing gear

Description

CNC Universal Grinding Machines for aircraft components OD-ID grinding-Turbojet Rotor shaft, landing gear grinding

AZ Universal grinding machines range has been designed to fulfil the requirements of a wide range of applications that combine external, internal, face and taper grinding of components such as: transmission shafts, electric motor shaft, gas turbine shafts, railway shafts, machine tools shafts, landing gear components, etc.

The machine can have WHEELHEAD MOVE or TABLE MOVE

Base made of Composital

X and Z axis movement on linear guideways

Headstock can swivel

Tailstock with hydraulic constant pressure controlled by load cell

Different clamping system and workpiece support

Wide range of wheelhead configurations: straight, angular, internal and “B”- axis

Silicon carbide, corundum, CBN and diamond grinding wheels allow grinding of different materials and surface treatments including Chromium and HVOF

Ideal machine for high demanding sectors

AEROSPACE, RAILWAY, PRINTING INDUSTRY, COLD MILLS, AUTOMOTIVE, INDUSTRIAL VEHICLES, SPINDLES FOR MECHANICAL ENGINEERING APPLICATIONS, ELECTRICAL GENERATORS ...

- Wide range of wheelhead configurations

- Different models with moving table or moving wheelhead

- Partial or total guarding

+ GAP BED OPTION TO ALLOW FOR LARGE DIAMETER SWING COMPONENTS

VIDEO

Catalogs

No catalogs are available for this product.

See all of AZ‘s catalogs*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.