Optical inspection machine bonNDTinspect® automaticsurfacefor NDT

Add to favorites

Compare this product

fo_shop_gate_exact_title

Characteristics

- Technology

- optical

- Other characteristics

- automatic

- Applications

- surface, for NDT

Description

Overview

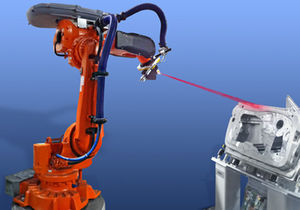

The fully automated and non-destructive bonNDTinspect® wettability test checks and verifies the paintability or bondability of assembly parts out of a variety of materials and over large areas.

Advantages

The wettability and thus bondability of the surfaces of assembly parts can now by inspected automatically, reliably and in-line. 100% of the entire surface is tested this way. This provides a key advantage over methods such as contact angle measurement or application of test inks which are primarily used in the laboratory. Because unlike bonNDTinspect®, these methods are merely used on a random sample basis. They also contaminate the test part during the testing process. Surface pre-treatments used to prepare parts for bonding, such as plasma activation of CFRP surfaces, are tested and characterised reliably by bonNDTinspect®.

The data obtained in this way allows for complete and automatic documentation of the inspection results. Permanent optimisation of the production process is possible this way. High costs incurred through the further processing of parts whose surfaces weren't properly prepared at the time of bonding or painting can be avoided with bonNDTinspect®. In addition to checking the pre-treatment steps, bonNDTinspect® also reliably detects contamination with silicon oils, grease and release agents.

VIDEO

Catalogs

No catalogs are available for this product.

See all of AUTOMATION W+R GMBH‘s catalogs*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.