- Production - Materials - Metrology

- Test equipment - Metrology

- Temperature test chamber

- Associated Environmental Systems

- Products

- Catalogs

- News & Trends

- Exhibitions

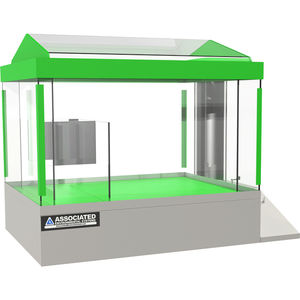

Temperature test chamber MX-9216aeronauticalbench-top

Add to favorites

Compare this product

Characteristics

- Test type

- temperature

- Other characteristics

- aeronautical, bench-top

- Capacity

15.6 ft³

- Temperature

35 °C, 46 °C

(95 °F, 115 °F)

Description

The unique features of the salt spray test chamber, allows you better observation and access to your corrosion testing. The construction is made of high-quality Lucite®️ plexiglass on five sides making it the only 360-degree view into the chamber workspace

Completely self-contained, the MX Series salt spray chambers allow for test items to be subjected to a corrosive environment without introducing other contaminants into the test area

STANDARDS. The standard MX-9216 salt spray test chamber has an atomizing nozzle that can be factory set to be compliant with the following standards:

ASTM-B117

MIL-STD-202H

MIL-STD-750F

MIL-STD-810H

MIL-STD-883K, with optional modification

MIL-STD-19500, with optional modification

HEATING SYSTEM. To ensure temperature uniformity in the test workspace, the unit uses two separate RTD sensors. One for holding and conditioning incoming water to an accurate 45.5°C (113.9°F). As the water is mixed with the salt solution and atomized the temperature falls. In the product workspace, a second RTD sensor holds the ambient temperature at a steady 35°C (95°F) as the fog fills the workspace

Salt Spray chambers are commonly used to evaluate the corrosive properties of:

Phosphated surfaces (with subsequent paint/primer/lacquer/rust preventive)

Zinc and Zinc-alloy plating (see also electroplating)

Electroplated chromium, nickel, copper and tin

Coatings not applied electrolytically (such as zinc flake coatings)

Organic Coatings

INSTRUMENTATION. The standard MX corrosion test chambers have two independent manual-set digital controllers ensuring the heated water being sprayed and the workspace air temperature are controlled to the desired setpoint

Other Associated Environmental Systems products

Corrosion/Salt Spray

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.