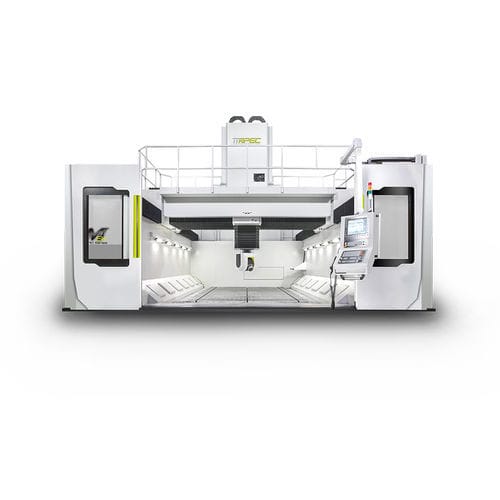

5-axis machining center SKM serieswith swiveling spindlefor the aerospace industryCNC

Add to favorites

Compare this product

Characteristics

- Number of axes

- 5-axis

- Spindle orientation

- with swiveling spindle

- Applications

- for the aerospace industry

- Other characteristics

- CNC, gantry

- Rotational speed

24,000 rpm

(150,796 rad.min-1)- X travel

4,000 mm, 5,000 mm, 6,000 mm, 8,000 mm

(157.48 in, 196.85 in, 236.22 in, 314.96 in)- Y travel

2,700 mm, 3,200 mm, 3,700 mm

(106.3 in, 125.98 in, 145.67 in)- Z travel

1,000 mm

(39.37 in)

Description

-5-axis simultaneous machining

-For aerospace aluminum machining

-Box-in-Box structure

-X/Y/Z-axis driven by linear motor

-Cross beam flushing system

-Complex chip removal system

Symmetrical geometry design with Box-in-Box structure of cross beam and saddle. Excellent force flow design decreases thermal deformation. High accuracy during high-speed machining can be performed.

Unequal thickness of Ram with honeycomb structure

Ram equipped with honeycomb structure performs the best balancing design and better geometry.

Crossbeam flushing system

A high-pressure pump with groups of powerful nozzles can quickly remove the chips.

Complex chip removal system

A dual-chip removal system with a large-capacity water tank could make coolant and chip removal stable.

5-axis simultaneous machining

5-axis machining accuracy difference is below 0.01mm.

Special spindle for aluminum alloy processing

Ultra-high-speed and power spindle with the best material removal rate.

X/Y/Z-axis driven by linear motor

All three axes are driven by dual linear motors.

Max. feedrate:60 m/min

Max. acceleration:5 m/sec²

Automatic attachment head exchange system

Different angle heads could be mounted to match various applications and it is best for machining in narrow spaces.

Automatic top-roof cover

Movable beam design of top-roof cover could prevent the spreading of chips and coolant liquid.

VIDEO

Catalogs

No catalogs are available for this product.

See all of APEC CNC‘s catalogs*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.