- Software - Simulation

- Software

- Test software

- ANSYS FRANCE SAS

Test software Sherlockanalysisthermal analysisdesign

Add to favorites

Compare this product

Characteristics

- Function

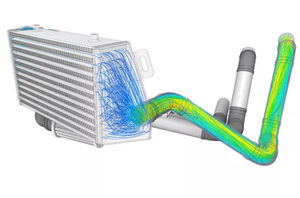

- test, analysis, thermal analysis, design, manufacturing, CFD

- Applications

- for aeronautics

Description

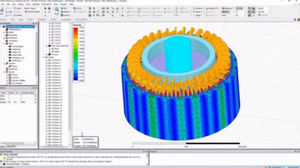

Ansys Sherlock is the only reliability physics-based electronics design tool that provides fast and accurate life predictions for electronic hardware at the component, board and system levels in early stage design.

Ansys Sherlock for Product Life Prediction

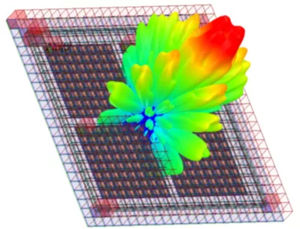

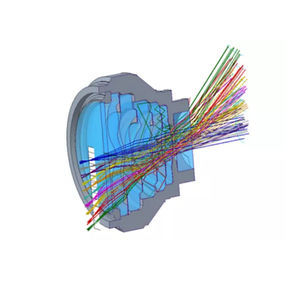

Ansys Sherlock provides fast and accurate life predictions for electronic hardware at the component, board and system levels in early design stages. Sherlock bypasses the ‘test-fail-fix-repeat’ cycle by empowering designers to accurately model silicon–metal layers, semiconductor packaging, printed circuit boards (PCBs) and assemblies to predict failure risks due to thermal, mechanical and manufacturing stressors--all before prototype.

Validated Time-To-Failure Predictions

Closed-loop Reliability Workflow with Ansys Mechanical, LS-DYNA & Icepak

Rapid ECAD to FEA and CFD Translations

Complete Product Lifetime Curve

Quick Specs

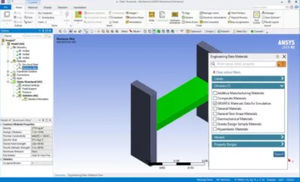

With embedded libraries containing over 300,000+ parts, Sherlock rapidly converts electronic computer-aided design (ECAD) files into computational fluid dynamics (CFD) and finite element analysis (FEA) models. Each model contains accurate geometries and material properties and translates stress information into validated time-to-failure predictions. Sherlock parts databases also include a link to Ansys Granta Materials Selector.

Drop Test Simulation

Locked IP Model

Default Package Geometries

Thermal Analysis Prep

Over 300,000+ Parts Library

Ansys Workbench Integration

PCB and PCBA Materials

Shock/Vibration/Thermal Cycling Analysis

1-D/3-D Solder Failure Predictions

Trace & Via Capture

Catalogs

No catalogs are available for this product.

See all of ANSYS FRANCE SAS‘s catalogs*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.