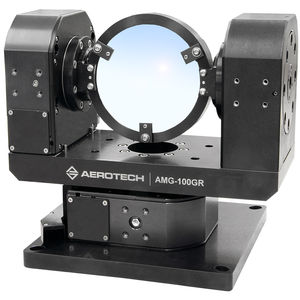

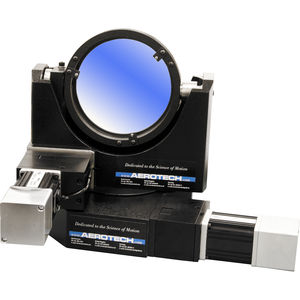

2-axis gimbal AMG high-precision

Add to favorites

Compare this product

Characteristics

- Number of axes

- 2-axis

- Options

- high-precision

Description

Design Features

Continuous 360 degree rotation of azimuth and elevation including built-in slip ring

High accuracy angular position and rate capability

Direct-drive brushless servomotors result in zero backlash

Cog-free design for outstanding velocity stability

Accommodate loads up to 600 mm diameter

Low maintenance and high reliability provide the lowest cost of ownership

Aerotech's AMG position and rate gimbal mounts provide ultra-precise angular position, rate and acceleration for development and production testing of a wide range of systems. The AMG series is ideal for directing optics, lasers, antennas and sensors at high speed to very precise pointing angles. Typical applications include missile seeker test and calibration, LIDAR, electro-optical sensor and FLIR testing, airborne target tracking, optical testing of space-based sensors in a vacuum and angular testing of inertial sensors such as gyros, MEMS, accelerometers and inertial reference units. The AMG gimbal design incorporates recent Aerotech rotary stage design improvements to provide high performance at an affordable price. The finest quality motors, bearings and encoders are integrated into precision-machined housings to ensure peak performance. The AMG position and rate gimbals provide precise angular motion with the high performance customers expect from Aerotech products.

VIDEO

Catalogs

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.