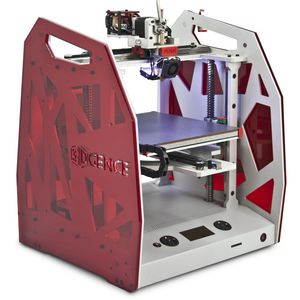

ABS 3D printer DOUBLE P255PLAFFFdesktop

Add to favorites

Compare this product

Characteristics

- Printed material

- ABS, PLA

- Heating technology

- FFF

- Other characteristics

- desktop

- Domain

- for the aerospace industry

- X travel

190 mm

(7.48 in)- Y travel

255 mm

(10.04 in)- Z travel

195 mm

(7.68 in)

Description

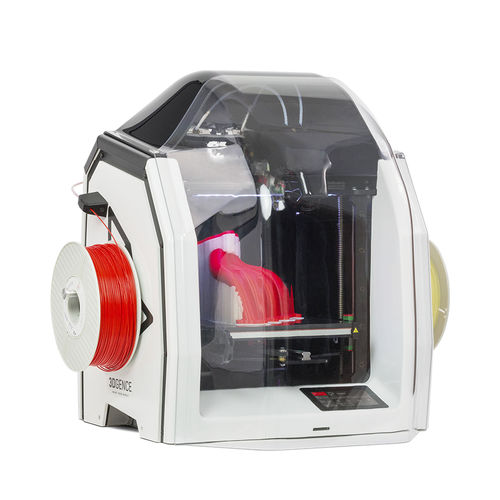

Dual-extruder 3D printer developed for professional use certified by TÜV Rheinland. Designed to create accurate parts with great detail using soluble support material.

Water soluble support

3D printing geometrically complex models

Remove supports from the 3D printed parts without any problems. Obtain elements with a certain mobility by rinsing filament in water.

Autocalibration

No need to calibrate the 3D printer manually

User involvement in the calibration process has been minimized as much as possible.

Dual swappable hotends

3D printing with multi-materials is possible.

The use of proprietary hotends guarantee high-quality parts 3D printed from model and support material. In addition you can swapped out hotend quickly without requiring any tools

Open material base

Working with all the primary materials used in FDM

3D print with all filaments available on the market, you are not restricted to a specific brand of filament

ABS

ABS is one of the most popular thermoplastics, regardless of production technology.

PP

Offers excellent print quality, high fatigue, mechanical strength and good thermal resistance.

PLA

Biodegradable thermoplastic polymer, that is produced out of renewable resources.

VIDEO

Catalogs

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.